Russian Federation Patent: №97423

Author: Tkachenko Yuriy Vladimirovich

Section of the IPC: B21F 25/00 – Barbed wire, mesh, fencing, wire fabrics

Section of the IPC: E04H 17/04 – Hedges, fences, paddocks, are characterized by the use of special purpose wires, such as barbed wire

Published: 27.04.2010

The security barrier "Cobra" – Russian Federation patent №97423

Usage: for construction of security barriers, which include barbed tape, barbed wire Egoza, which are used as barriers to prevent the unauthorized entry of people and animals on sensitive sites.

The inventive security barrier comprises at least one protective element is formed as a single twisted spiral barbed tape with its supporting multiple nodes at intervals from one another. Barbed tape shielding member is wound on the outer frame formed by several line segments strung barbed tape, the ends of which are fixed to the rays of the multipath components. These elements are mounted for free rotation about the longitudinal axis of the protective element in bearings mounted on support nodes. To make the overall stiffness protective element during its considerable length, inside the frame placed multipath analogous elements in any number, the ends of beams which protrude beyond the edges of the barbed tape envelope spiral outer frame. Inside the outer frame is disposed at least one, inner, coaxial, frame construction with a similar wound on a barbed tape similarly. External and internal frames coaxial electrically insulated from one another to be able to take stock of electric current separately to each frame. The security element may be provided with forced rotation occasion its multipath components. The rays of multipath components may be provided with additional striking elements in the form attached to them in a random order or symmetrical sharpened pins of different lengths or sharp spikes, or barbed tape wrapped. Technical advantages: increased protective properties; enhancing the overall stiffness of the security element; increasing destructive properties; increasing the deterrent effect; improving the efficiency and reliability of the protection of sensitive sites. 1 is independent.

The invention relates to the field of building security installations and systems, which include barbed-cutting elements, such as barbed wire Egoza and can be used for the manufacture of security barriers erected to prevent the unauthorized entry of people and animals on sensitive sites.

The well-known barrier to protect against thieves, cattle and other large animals, which contains the horizontal bar of a metal bracket fixed to the vertical column and vertical fence welded to said crossbar with a certain interval. Poles and fence made of metal rolling straight dihedral angles. The upper ends of the pillars and are fence length each right dihedral angle to form a stud at this end [see Russian Federation patent №2296203 class E04N 17/14 published in 27.03.2007].

The main disadvantage of this barrier is the lack of protective properties against thieves and intruders. This disadvantage is explained as follows. Since the barrier has a flat design and fence installed at regular intervals from one another, you can easily take hold of the horizontal model between fence and easy to climb over the barrier without damaging of thorns. Thus, a well-known barrier is only effective as a barrier for large animals, but is not effective as a security barrier against intruders.

This disadvantage is eliminated in the security barrier "Dikobraz", consisting of a set of spherical protective elements, each of which includes a reinforced twisted barbed tape and barbed wire wound on the wire-base or barbed tape compression at the portion of the side surface of the wire-base Formation in space frame. The space frame is formed in the shape of a sphere formed meridional windings wound or crimped barbed tape and rigid equatorial ring installed inside the coils wound or crimped barbed tape. Coils wound or crimped barbed tape bonded to each other at the poles of the sphere and the equatorial ring. Security barrier erected follows. Ready first spherical protective element is attached to a vertical or inclined stand at the poles of the sphere and on-site security abroad. Further, adjacent to the first spherical protective member disposing the second, third and so on similar spherical protective elements over the whole length of the safety barrier, forming a protective boundary [see Russian Federation patent №2272113 class E04N 17/04 published in 20.03.2006].

The main drawback of this security barrier is spherical protective elements are not bonded to each other along the length of the security boundary. Therefore, any of them are quite easy to rip off the counter or delay by tilting it down, capturing, for example, a conventional hook to form a free passage through the protective line as the rest of the spherical protective elements prevent such failure or limb of one of them: after all, the spherical elements are not linked. And it is this fact (lack of unity and integrity of the structure over the entire length) dramatically reduces the effectiveness of the protection of sensitive sites using a known security barrier.

The closest in its in its essence and attainable effect is taken as a prototype, is a security barrier comprising at least one protective element is formed as a single twisted spiral barbed tape with its supporting multiple nodes at intervals from one another. Security elements in the form of a single spiral barbed tape may be somewhat near one above another in a vertical plane forming vertical section of the barrier, and the single helix of the barbed tape may have different diameters. A single turn of the spiral of the barbed tape attached to the support sections of nodes in two places, which allows you to create horizontal and vertical resistant barrier [see the International applications №WO 2007/078307 for Class V2LF 25/00 published in 12.07.2006].

The main disadvantage of this barrier is its low barrier properties. It’s fairly easily overcome, since its protective element is fixed relative to the support nodes. This circumstance – the immobility of the security element – allows it to cover any sheet material, for example, a tarpaulin, and that is how to completely eliminate the effects of prickly-cutting teeth submunitions barrier. Furthermore, the submunitions, in this case, on the contrary, even an attacker will have some help hold sheet material barbed prongs belt from slipping, allowing it to easily overcome the barrier by climbing over the protective element and thus penetrate regime object.

Another essential disadvantage of the known barrier structures are deficient its security element, which also reduces its protective properties as a whole. This drawback is that the protective element is a single twisted spiral barbed tape. For the formation of free passage through the barrier, just once anywhere bites or cut the barbed tape: because she is single. Cut the spiral works like a spring, and "automatically" open a free pass. If the barrier has only one barbed tape, it is particularly vulnerable.

The basis of the utility model the task of raising the technical and operational characteristics and capabilities of a security barrier, and also enhance the security of sensitive sites due to the impossibility of placing it all coverings to neutralize the harmful effect of sharp prongs barbed tape and by difficulty breaking the integrity of the security element by performing last movable relative to its support nodes, as well as the protective member coaxially double.

The solution of this problem is achieved by the security barrier comprising at least one security element in the form of a single twisted spiral barbed tape with multiple support his units, spaced at intervals from one another, according to the proposal, barbed tape security element is wound around the outer frame formed by multiple tensioned straight segments barbed tape, the ends of which are fixed to shafts of multi shafts elements mounted freely rotatable about the longitudinal axis of the protective element in bearings mounted on support nodes as well as to impart a total hardness protective element during its considerable length, inside the frame placed multipath similar elements in any amount, the ends of which beam within the dimensions of the barbed tape helically Envelope frame further inside the outer frame is arranged at least one inner frame is of similar design to the wound on a barbed tape similarly.

To increase the deterrent effect of aggressive or protective member may have forced the rotational drive of its multipath components.

To enhance the effect of damaging rays of the multipath components can be provided with additional striking elements in the form attached to them in a random order or symmetrical pointed pins of different lengths, or sharp spikes or wrapped barbed tape.

To enhance the effect of damaging the outer and inner coaxial frames can be electrically insulated from one another to be able to take stock of electricity to the inner frame.

Due to the fact that the security element is movable, in particular turning in the horizontal plane, it is impossible to fix any coating or grab hold of the barbed tape or beams and tightened. In both cases, due to the eccentricity of load application arm relative to the axis of rotation, multipath components required to crank bearings and do not allow an attacker to climb over the protective element.

Thanks to the supply of electricity to the inner frame, the protective properties of the protective element are amplified. If an attacker tries hard to overcome the barrier of security and destroy the outer frame, he turned up additional electric shock from the internal frame while trying to overcome it by any means. Thus, the proposed barrier ensures the achievement of the technical result of the assigned tasks.

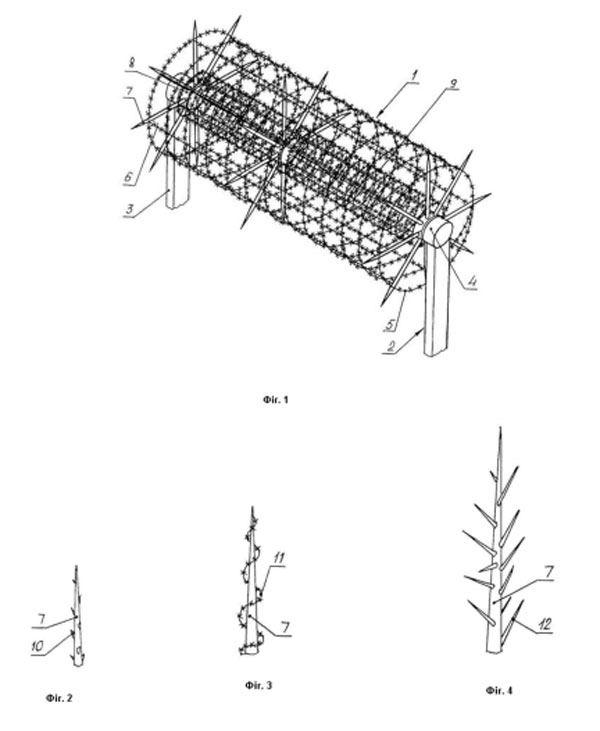

Further essence of the proposed technical solution is explained in conjunction with illustrative pictures, showing:

- Figure 1 – a plan view of the proposed security element with one additional inner frame.

Options Snap-shaft multipath components additional striking elements:

- Figure 2 – shaft with sharp spikes;

- Figure 3 – shaft coiled barbed tape;

- Figure 4 – beam with sharp pins.

Each section of the proposed security barrier comprises a protective element 1 is situated predominantly horizontally and mounted on its supporting units 2. The support units 2 are made in the form, preferably, uprights 3 with the radial bearing 4 at its upper end.

The protective element 1 has a twisted spiral barbed tape 5 wound on the outer frame, formed by several straight line segments strung barbed tape 6, the ends of which are fixed on the beams 7, 8. The multipath components of multipath components 8 are mounted for free rotation about a central longitudinal axis of the protective element 1 in the bearings 4.

To make the overall stiffness protective element 1 at its considerable length, within a frame can be arranged similar multipath components 8, in any amount, and the end of which beams 7 protrude beyond the edges of the barbed tape 5, the envelope of the spiral cage.

Inside the outer frame is arranged at least one inner frame 9 similar constructions with wound on a barbed tape 5 in a similar manner. To enhance the damaging effect of the outer and inner coaxial scaffolds may be electrically insulated from one another in any known manner, for example by means of insulating sleeves (they are not shown because of common knowledge) worn by beams 7 for possible summing electricity to the inner frame 9, which extends the protective properties of the proposed barrier.

To increase the aggressiveness or deterrent effect, multipath elements 8 may be provided with positive drive of the rotation of any known construction (they are not shown because of the notoriety). Forced rotation of multipath elements 8 causes the rotation of the frame with barbed tape 5, which improves the visual aggressiveness of the security fence and is used when an attempt to penetrate the regime object becomes apparent.

To enhance the striking features of multipath shafts 7 elements 8 can be provided with additional striking elements in the form attached to them in a random order or symmetrical sharp spikes 10 or wrapped in barbed tape 11 or secured pointed pins 12 of different lengths.

The proposed barrier operates as follows:

When someone is trying to grasp the barbed tape 5 or 7 rays of hands and tightened security element 1 twist necessarily with multipath elements 8 around the longitudinal axis, and the area for which the seized arms, would be at the bottom, it will not allow climbing over the security element 1. When attempts to intercept arms for barbed tape other areas 5 or for other Rays 7, all happen again thanks to the next turn of the security element 1 with multipath elements 8 bearing 4. The same thing happens when you try to cover the protective element 1 in any sheet material: when you try to get into this material due to the eccentricity, the security element 1 will rotate, giving an attacker to climb on the security element 1. Therefore, climb over the barrier of the proposed design is not possible.

In addition, the presence of additional rays 7 striking elements in the form of spikes 10, barbed tape 11 or 12 pin pointed in general makes it impossible to grasp their hands, even to a greater extent, increase the barrier properties of the proposed security barrier.

Running skeletons of several line segments strung barbed tape 6 that spiral round the prickly tape 5 does not allow the latter to spring back when cutting: spiral turns necessarily cling to the striking elements of line segments barbed tape 6 However, if an attacker is trying hard to overcome the barrier of safety and destroy the outer frame, it is covered by the electrical current supplied to the inner frame 9 when trying to overcome it.

Clearly, the security element can be used as a security barrier, and without its supporting units 2. In this case, it simply laid on the ground or the road. That is, the protective element can act as a standalone product is protective. It is also understood that the inner frame cannot supply electric current when it is not needed.

Essential difference of the proposed technical solutions from the prior art, lies in the fact that the security element is movable, in particular rotatable, with the optional inner frame, to which can be supplied electric current, and the rays of multipath components are equipped with additional striking elements in the form of spikes, tapered pins or barbed tape. These differences, together, preclude any possibility of overcoming the security element by rotation of the security element in the case of the application to it of any load, or hitting electric persistent intruders. And it is this fact allows us to consider the proposed barrier is almost irresistible. None of the following safety barriers can possess distinguished properties since their protective elements are either fixed, or they do not have structural integrity in length, or have no additional coaxial elements or have, but they alone cannot bring electric current due to the lack of appropriate isolation.

The proposed technical solution tested in practice. The security barrier "Cobra" does not contain any elements and components that can be replicated at the present stage of development of science and technology, in particular, the production of safety barriers and protective fences, hence, its design is industrially applicable, has the technical and other advantages over known such technical solutions, thanks to the proposed principle of fixing the protective element to the support of its units and equip additional coaxially mounted a protective element, which confirms the possibility of achieving a technical result of the claimed subject, in certain sources of information not found similar security barriers mentioned in the proposal essential features, but because considered as such, it can receive legal protection.

The main technical advantages of the proposed technical solutions, in comparison with the prior art, include the following:

- Increase the protective properties due to the fact that the protective element is a rotary element with respect to its support;

- Increasing the overall stiffness of the security element in its considerable length due to the presence of intermediate multipath components;

- Increasing destructive properties due to multipath rays snap elements additional striking elements;

- Increase the protective properties due to snap a protective element;

- Compact construction due to the coaxial arrangement of an additional protective element generally;

- Summing up the possibility of a separate electric current to the internal security element by equipping rays insulators;

- Increasing deterrent effect due to the forced rotation of the security element;

- Improving the efficiency and reliability of the protection of sensitive sites due to the impossibility of overcoming the barrier.

Social benefits from the implementation of the proposed technical solution are compared with the prototype obtained by the impossibility of penetrating sensitive sites.

The economic effect of the introduction of the proposed technical solution, as compared with prior art, obtained by ease of manufacture and use of a security barrier for a common parts and materials.

After the description of the proposed barrier, specialists in the given area should be apparent that all of the above is merely illustrative, and do not limit, having been presented by this example. Numerous possible modifications of the security element, in particular, the number, size barbed tape used actuators and bearings, variants of ribbons frames, number, length and thickness of the rays of multipath components, the design of the inner coaxial shielding member may vary in different ratios, and clear are within the scope of one of ordinary natural and approaches in this area of knowledge, and such are considered that are within the scope of this technical solution.

The quintessence of the proposed technical solution is that the protective element is turning, it is located coaxially additional protective element of this design, which can supply electric current, and the rays of multipath components are equipped with additional striking elements, and that these factors, combined, allow purchasing the offer security barrier above and other advantages. Change and use of only the individual components of a security barrier, of course, limits the range of the benefits listed above, and cannot be considered as new technical solutions in the field of knowledge, as other, similarly to the security barriers no longer require creativity from the designers and engineers, and therefore cannot be considered the results of their creative activity and new intellectual property that fall under the protection of enforcement documents.

Formula utility model

- The security barrier comprising at least one protective element is formed as a single twisted spiral barbed tape with multiple supporting units mounted at intervals from one another, characterized in that the security element barbed tape is wound on the outer frame, formed by several straight strained segments of barbed tape, the ends of which are fixed to beams of multi shaft elements mounted freely rotatable about the longitudinal axis of the protective element in bearings mounted on support nodes as well as to impart a total hardness protective element during its considerable length, inside the frame has a similar multipath elements any amount rays which ends protrude beyond the edges of the barbed tape helically envelope frame further inside the outer frame is arranged at least one more internal, coaxial with the carcass structure similar wound on a barbed tape similarly.

- The security barrier according to claim 1, characterized in that the inner and outer frames electrically insulated coaxial from one another to allow electric current summing separately for each frame.

- The security barrier according to claim 1, characterized in that the protective element is equipped with a forced rotation drive its multipath components.

- The security barrier according to claim 1, characterized in that the rays of multipath components are equipped with additional striking elements in the form attached to them in a random order or a symmetrical sharpened pins of different lengths or sharp spikes, or wrapped barbed tape.