Patent of Ukraine: №48667

Author: Tkachenko Yuriy Vladimirovich

Section of the IPC: B21F 25/00 – Barbed wire, mesh, fencing, wire fabrics

Published: 25.03.2010, Bulletin № 6/2010

The security barrier Piranha – the Patent of Ukraine №48667

- Barbed tape, which is obtained from a metal band (models), comprising a central portion and a large quantity of submunitions, integrally formed with it, which is characterized in that the submunitions are arranged along the central area of the belt uniformly shifted by half the striking element on each sides of the central portion. Moreover, each arresting member is in the form of an equilateral triangle with straight sides directed perpendicularly from the central portion, and spine-vertex, wherein the tips of each studs are the angle between the sides of the triangle.

- The barbed tape point 1, which is characterized in that the triangle has both curved so deep into the concave side.

- The barbed tape point 1, which is characterized in that the triangles have one side of the central portion of one size, and the second – the other.

- The barbed tape of point 1, which is characterized in that the triangles at one side of the central portion have a different resolution.

- The barbed tape point 1, which is characterized in that it is made of twisted about the longitudinal axis of the belt.

- Barbed tape n. 1, which is characterized in that it is made wavy or entourage into a spiral.

- Barbed tape point 1, which is characterized in that the submunitions-triangles are bent away from the plane of the central portion in one direction, and in different directions.

The utility model belongs to the metal production, namely, the production of barbed tape, which is used as safety barriers are designed to prevent unauthorized penetration of sensitive sites.

A method for manufacturing the barbed wire, which consists in the fact that in the tape punched along wasps symmetry perforations grooves which fix stellate shafts inserted in the slots belt angle which is oriented in the opposite direction from others, and a side the other corners of the tape is folded around the cleat rolled and between grooves spin around its longitudinal axis [see the copyright certificate USSR №519256 class B21F25/00 published in 25.06.1976].

The main disadvantage of this method include the complexity of manufacturing the product, its high cost and unreliability of the stud affixing positions in the tape.

It is also well-known barbed tape that obtained from metal strip and comprises a central portion and a large number of opposed pairs of elements which are integrally formed with it, each element of the element pairs is provided with first and second external spines and third and fourth internal spines which are formed by punched oval slots in the tape [see the USA Patent №4887796 of class B21F25 / 00 published in 19.12.1989].

The main disadvantages of known serrated tape is its lack of humanity – a form of external spikes facilitates application of serious wounds and injuries, a relatively large distance between the axes of symmetry of the adjacent pairs of elements that do not provide sufficient retention effect of fragments of clothes and body of the offender, the high cost of manufacturing the tape because the it is made from stainless steel that requires a lot of energy, increased wear and stamping services, metal stamping at its stamping irrational, the shape of the external and internal spikes form large metal waste.

The closest in its essence and the attainable effect, and which is accepted as the prototype, is a barbed tape, which is obtained from a metal strip, which comprises a central portion and a large number of opposing pairs of submunitions which are integrally formed with it, wherein a pair of submunitions located along the central section of the tape evenly, and each striking element in the pair composed from the base, and oppositely directed thorns made of external sides of the element, and the tips of each of the studs is the corners which are formed between the outer side and the sides of the element, wherein between the sides of elements located near pairs of elements, formed by a wide inner space bounded by the outside spikes of these elements [see the Patent of Ukraine №41834 of class B21F25/00 published 24.04.2001].

The main disadvantage of the known barbed tape is that with its help it is impossible to build a reliable barrier boom due to insufficient barrier properties of the barbed tape. The presence of this lack is explained as follows. Spikes damaging elements are directed along the central portion of the tape as it is located on the outer sides of the striking element. This spatial orientation of thorns does not prevent an attacker to grab the hand of the tape, in particular, cover the striking element and pull or bend the tape in any direction. This hand will not experience any injuries due to the fact that the submunitions are no spikes, which would be aimed at least at some angle to a longitudinal axis of the tape, that is, the outer side of submunitions smooth, without any elements pointed at it.

Another essential disadvantage of the known barbed tape is inefficient use of the model material (the metal strip) by the formation of metal waste during punching in the strip a large number of opposing pairs of damaging elements to form a wide inner space in which the tip directed spikes. Such waste reaches 30% of the preform.

The basis of the utility model is the task of improving the protective properties of the barbed tape and efficiency of the model material by reorienting the spatial arrangement of spikes by changing the design of submunitions.

The solution of this problem is achieved by the fact that barbed tape that is obtained from a metal strip (blank) comprises a central portion and a large number of submunitions that are integrally formed with it, according to the proposal of the striking elements are arranged along the central portion of the tape is uniformly offset by half the striking element on each side of the central portion, and also one arresting element has the form of an equilateral triangle with straight sides directed perpendicularly from the central portion, with the top-thorn and cusps each of the studs is the angle between the sides of the triangle.

- The triangle can be both curved so deep into the concave side.

- Triangles may have on one side of the central portion of one size, and on the other.

- Close triangles at one side of the central portion may also have different sizes.

- Barbed tape can be performed both flat and twisted relative to the longitudinal axis of the tape.

- Barbed tape can be executed as straight or wavy, or entourage into a spiral.

- Striking elements, triangles can be bent away from the plane of the central portion in one direction, and in different directions.

Since the sharp spikes damaging elements are perpendicular to the central portion of the barbed tape, for it is impossible to grasp without injured hand palm that is impossible to pull or bend the tape in any direction and thus make a free passage through the protective barrier.

In the manufacture of the proposed barbed tape comes wholly-use model material (metal strip), that is, without the generation of waste metal in the recess in the strip triangular submunitions. After all, if used as a billet wide metal strip, is released from the metal space between the triangles of a barbed tape automatically become triangular striking elements of the second barbed tape. Therefore, from a wide metallic tape can be manufactured without waste multiple barbed tape. In doing this, not only the waste-free production process, but also increase productivity by at least half.

Consequently, the proposed design changes barbed tape can achieve the technical result indicated in the statement of the problem, namely: increasing the protective properties of the barbed tape and efficiency of the model material.

Further the nature of the proposed utility model is explained in conjunction with illustrative material, which shows the following:

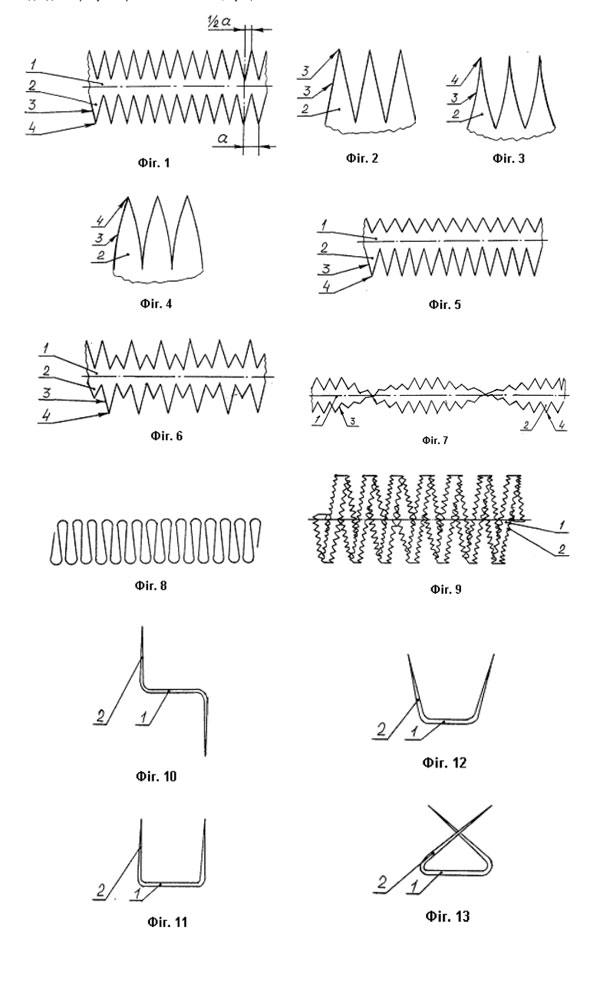

- Figure 1 – a general view of the proposed barbed tape striking elements positioned coplanar with the central portion of a top view;

- Figure 2 – view of a triangular striking elements with straight sides;

- Figure 3 – view of a triangular element with striking deep into the concave sides;

- Figure 4 – view of a triangular element with striking curved outwards parties;

- Figure 5 – perspective view of the barbed tape with different sized striking elements on one side of the central portion;

- Figure 6 – the general view of the barbed tape with different sized striking elements on each side of the central portion;

- Figure 7 – general view of the barbed tape twisted about the longitudinal axis;

- Figure 8 – a side view of a wavy barbed tape;

- Figure 9 – general view of the barbed tape wound in a spiral;

- Figure 10 – section of barbed tape bent in different directions submunitions;

- Figure 11 – section of barbed tape bent to one side of the striking elements and parallel arrangement of submunitions;

- Figure 12 – section of barbed tape bent striking elements in one side with an arrangement of submunitions at an obtuse angle;

- Figure 13 – section of barbed tape bent striking elements in one side of a reticle submunitions.

The following barbed tape "Piranha" is made of metal (for example, cold-rolled galvanized steel) strip and consists of the central portion 1, and a large number of submunitions 2, which are formed integrally with it (1). Elements 2 are disposed along the central portion of the tape 1 is uniformly shifted by half the striking element 2 (1/2) on each side of the central portion 1. Clearly, striking elements 2 may be arranged unevenly, but it complicates only the equipment and the technology of manufacturing the belt. Therefore, technologically elements 2 complying with a uniform distance from each other.

Each striking element 2 has the form of an equilateral triangle, which extends perpendicularly from the central portion 1, with the top prongs 3 and the tips of each of the studs 3 is the angle between the four sides of the triangle. Triangular striking element 2 may have four rectilinear sides (2), or four sides, which are concave depth of the triangle (3) or four sides of which triangle is arched outwards (Figure 4). Triangular submunitions 2 may be on one side of the central portion 1, one size, and the second – the other (5). Close triangular elements 2 on one side or on each sides of the central portion may also vary in size (Figure 6). Barbed strip may be formed as a plane (1) and twisted about the longitudinal axis of the tape (7). Barbed strip may be made as a straight line (1) and undulating (8), or wound in a spiral (9). In the latter case, the triangular submunitions 2 expedient bent from the plane of the central portion. Triangular submunitions 2 may be bent away from the plane of the central portion 1 in the opposite sides (10) and parallel to one side (11) or at an obtuse angle (12), or with reticle (13) elements 2. It is for the latter case it is necessary that submunitions 2 are disposed along the central portion of the tape 1 is uniformly shifted by half the striking element 2 on each side of the central portion 1. Only then (offset) can be performed by three studs their cross. If the spikes do 3 with uneven pitch or without offset, such an embodiment of the barbed tape cannot be obtained. However, this version of her performance is most effective: 3 spikes oppositely directed, and reticle barbed tape provides additional common longitudinal stiffness.

The given barbed tape "Piranha" is as follows.

When you try to overcome the barrier, using the proposed barbed tape elements 2 Hold the attacker without inflicting serious wounds and injuries and retain fragments of clothing and body of the offender, who clung to the thorns 3. clutched his hands to free the tape is not possible, as spikes 3 are directed from the central portion 1 and are arranged without space between them. Hence the attacker or offender protection regime is forced to wait for guards to be released by them. Thus, the proposed barbed tape form enables a reliable protective barrier protected sites and comply with certain humanity without causing serious injury and injury offender spikes 3 barbed tapes.

Essential difference of the proposed utility model from previously known similar solutions is, that the submunitions are directed perpendicularly from the central portion of the barbed tape and in that the submunitions are made in the shape of triangles of different sizes with spikes that (triangles) may be deployed any side at any angle. These differences, in aggregate, significantly increase the protective properties of the barbed tape, simplify the technology of its production, the opportunity to bring waste-free production, and a variety of performance spikes and bending, as well as many options for bending the tape itself, and significantly expand the scope of the proposed use of barbed tape. No known barbed tape may not have the mentioned properties, because they have traditionally spikes, wherein the direction of the tip along the central area of the belt, which means the presence of binding between the two cavities, a metal of which falls into the waste.

The technical advantages of the proposed technical solution, as compared to the prototype include the following:

- Increase the barrier properties due to the proposed orientation of studs relative to the central portion of the barbed tape;

- Non-waste production barbed tape because of the execution of the damaging elements in the form of triangles;

- Extension of the application due to the large variety of options like bending submunitions and the most barbed tape.

The social impact of the proposed use of a utility model is in comparison with the prototype, obtained by increasing the reliability of protected objects, expanding the range of protected objects.

Economical effect of the use of the proposed utility model, in comparison with the prototype prepared by the savings due to the use of metal waste technology, and reduce the cost of the barbed tape by simplifying the equipment, and hence its cost.

After the description above of the barbed tape "Piranha", specialists in the given area should understand that all of the above is merely illustrative, and do not limit, having been presented by this example. Numerous modifications and other embodiments of the submunitions barbed tape, in particular, their size and shape may vary in different ratios and constructively that certainly within the scope of one of ordinary and natural approaches in the art knowledge and are considered to be within the volume of the solution.

The quintessence of the proposed technical solution is that the central area of the belt deviate triangular submunitions, spikes which are not parallel to the axis of the tape, and can be bent in any direction, even though the screw, and this circumstance makes it possible to receive the tape above and other advantages. Fabrication, modification and use of only certain elements of the belt, of course, limits the range of benefits mentioned above, and cannot rely on new technical solutions in the field of knowledge, as more similar to that described pursuant barbed tape does not require any creativity of designers and engineers, and therefore and cannot rely on the results of their creative activity and new intellectual property to be protected by security documents.