Russian Federation Patent: №2412774

Author: Tkachenko Yuri Volodimirivich

Section of the IPC: B21F 25/00 – Barbed wire, mesh, fencing, wire fabrics

Published: 27.02.2011

Rolled reinforced barbed tape "Caiman" – Russian Federation patent №2412774

The invention relates to the production of protective spiny reinforced tapes, such as barbed wire Egoza, and it can be used for the construction of safety barriers. The tape is formed from metal strip and comprises a central portion with opposite pairs of basic elements, formed integrally with it and located in a plane along the central area of the tape with a uniform pitch. Each main striking element in a pair consists of a base and opposing prongs, formed on a side of the element. Spearheads of each prong are the angles formed between the outer and inner sides of the striking element. By the side of the main elements affecting disposed adjacent the internally broad space for the placement of additional damaging elements with prongs directed toward his sharp prongs basic elements. The central portion of the tape is reinforced with an elastic element in the form of wire, fixed and held on the rolled tape edges of the central portion. Primary and secondary elements are arranged at different angles relative to each other along the tape, varies from 0 ° to 90 °, and provided with one or more spines arranged perpendicular to the longitudinal axis of the tape. Improves the barrier properties are retained elastic properties and shape.

The invention relates to hardware production, and more specifically to the production of reinforced barrier tapes used for the construction of safety barriers designed to prevent unauthorized penetration of sensitive sites.

The well-known barbed wire, obtained from a metal strip, wherein the pre-pierced along its axis of symmetry of perforated recesses in which the fixed stellate spikes mounted in said grooves of the tape at an angle oriented in the opposite direction from the alignment of adjacent studs, and the tape is bent around the spike and seamed, the grooves between tape is twisted around its longitudinal axis [see copyright certificate USSR №519256 class B21F 25/00, published in 25.06.1976].

The main drawback of known barbed wire includes the complexity and laboriousness of its manufacture, due to punching slots in the metal strip manufacturer spikes as separate elements to be assembled tape with spikes that, in general, increases its cost, low unreliability fastening studs in the grooves of the tape which reduces its protective properties.

Also it is famous also serrated tape obtained from a metal strip and comprising a central portion with a large number of opposing pairs of elements, formed integrally with it. Each element in the pair is provided with first and second external prongs and the third and fourth – internal prongs, formed by the punched tape in oval grooves [see US Patent №4887796 class B21F 25/00, published in 19.12.1989].

The main disadvantages of the known serrated tape are its inhumanity against the alleged attacker that is a form of external serrated type promotes deposition of serious injuries and mutilations. Moreover, the tape has a relatively large distance between the axes of symmetry of the adjacent pairs of elements that does not provide a sufficient retention effect fragments clothing and body intruder and the tape has a relatively high cost due to the fact that it is made from stainless steel, the treatment of which requires a relatively high energy costs, an increased depreciation and stamping services, metal stamping at its stamping – irrational because of the specific form of external and internal serrated type, resulting in a lot of waste metal.

Also known barbed tape comprising a central portion and a large number of opposed pairs of elements, integrally formed with it, wherein a pair of elements disposed along the central area of the tape uniformly, and each element in a pair consists of a base and an oppositely directed serrated disposed on the outer sides of the element, and each of the tips of the prong are angles formed between the outer side and the sides of elements, wherein between the side of the element, pairs of adjacent elements formed inside the wide space which is bounded externally sharp prong of these cells [see Ukrainian Patent №41834 class B21F 25/00, published in 24.04.2001].

The main disadvantage of the known barbed tape is that with its help it is impossible to create a reliable barrier fence due to lack of technical and functional capabilities of the barbed tape, namely: firstly because of the famous barbed tape is made of lamina metal, it is easy to bite (cut) without the use of a special tool for this purpose (you can cut even by ordinary household scissors), and, thus, affect the integrity of the fence protected object. Secondly, since the known barbed tape does not have sufficient elastic properties and having a small thickness of the metal from which it is made, barricade erected from such tapes, are easy to deform, for example clamped to the ground (even an ordinary stick) and freely penetrate protected object. Moreover, such a tape, after the forced deformation, due to lack of the elastic properties of the metal from which it is made, is not returned to its original state.

These drawbacks are eliminated in a barbed tape comprising a central portion and stamped on the outside of the trapezoidal spikes with decreasing to the base angles of taper, wherein the tape further comprises a reinforcing wire of circular cross section forming its core, which is wrapped or crimped by tape adjacent to the surface of the central portion and the spikes are arranged opposite to one another on different sides of the longitudinal axis of the tape [see Russian Federation patent №68386 U1 class B21F 25/00, 29/00 F41H 11/08, published in 27.11.2007].

The main disadvantage of this is the ability of the barbed tape spontaneous separation of the core from the tape during flexing of the latter, because the contact between the tape and the core is only on the tangent line.

This drawback is eliminated in the rolled reinforced barbed tape formed from a metal strip and comprising a central portion and a large number of opposing pairs of elements, integrally formed with it, wherein a pair of elements disposed along the central area of the tape with an uniform pitch, and each element in the pair comprises base and opposing prong, formed from the outer side of the element, and the tips of each of the prongs are angles formed between the outer side and the inner side member, wherein between the sides of the elements adjacent pairs of elements is formed inside the wide space outwardly bounded cusps prongs of these elements, moreover, the central portion of the tape is reinforced with an elastic element, preferably of circular cross section, attached to the tape seamed edges of the central portion of the same tape. Reinforcement tapes with central elastic member in the form of wire made for example from high-carbon steel with pronounced elastic properties itself bending of the central portion during operation mounting (rolling) of the wire from the flat shape to the cylindrical attached tape sufficient rigidity and elasticity to retain and restore it its original form, given to her by the manufacturer at the time of manufacture. Barbed tape with properties capable of creating a high-performance long time without changing their elastic properties of a physical barrier to prevent unauthorized access to the protected area [see patent of Ukraine №33526U class B21F 25/00, published in 25.06.2008].

The main disadvantage of this barbed tape are insufficiently effective retention properties, in particular if the attacker clothing catches on the spike, the clothes can be easily freed since it is not obstructed because a design tape no oppositely directed elements which could with spikes build retaining "harpoon" effect.

The closest in its essence and attainable effect, received the prototype is rolled reinforced barbed tape formed of metal strip and comprising a central portion with a large number of opposing pairs of basic elements integrally formed with it and arranged in a single plane, and a pair of core elements located along the central area of the tape with a uniform pitch, and each core element in a pair consists of a base and opposing prong, formed on a side member, and the tips of each of the prong are angles formed between the outer and inner sides of the element, wherein between the side cell sides, adjacent pairs of basic elements is formed inside the wide space outwardly bounded sharp prongs of these basic elements, inside said wider space there are additional tine towards its cusps meet sharp prong basic elements and located in the same plane as the main elements and, moreover, the central portion of the tape is reinforced with an elastic element in the form of wire, preferably of circular section fixed and held on the rolled tape edges of the central portion of the same tape. Reinforcement tape central element manufactured, for example, from steel high carbon wire with expressed elastic properties itself bending of the central portion during the operation of wire rolling which it is in flat form becomes cylindrical, gives barbed tape sufficient rigidity and resiliency for the preservation and restore its original shape given to it by the manufacturer in the manufacturing process [see the USA Patent №4844422 class B21F 25/00, published on 30.07.1987].

Despite the fact that the additional prong elements increase the retention effect, but the location of the main and additional elements in a single plane reduces the overall barrier properties known barbed tape, since the flat tape is easy to press or push even a hand resting the palm on the plane on which the missing prong elements (the plane on which the sharp prongs are not directed). In addition, the basic elements of all possible cover hand freely, as the tip of the prongs are directed either parallel to the central axis of the tape, or at some slight angle away from it, that is, they cannot cause hand injuries. The same tape capture can be done by hand and for additional elements, if the space between the main elements will be so broad that it would be possible to take the hand of the additional elements, not clinging to the palm of the prongs of the main elements affecting. Therefore, the design of the famous rolled reinforced barbed tape is vulnerable and, therefore, it is necessary to recognize the unimproved, because you can freely manipulate (move, turn down, pressed to the ground), even your hands without injury, especially mutilations.

The basis of the invention is to improve barrier-protective of the consumer-physical properties rolled reinforced barbed tape by increasing the damaging effect by arranging the gear elements in different planes along the length of tape and supplies it with additional striking elements extending from its central longitudinal wasp almost perpendicular.

This object is achieved by the fact that the known rolled reinforced barbed tape formed of metal strip and comprising a central portion with a large number of opposing pairs of basic elements, or integrally formed with it and arranged in a single plane, and a pair of major destructive elements are arranged along the central portion tape with uniform pitch and also every main striking element in a pair consists of a base and opposing prongs, formed on a side of the element, and the tips of each of the prongs are angles formed between the outer and inner sides of the striking element, wherein between the sides basic damaging elements located adjacent the internally wide space, external constraints sharp prongs themselves basic elements, and within said wide area there are additional elements, prongs which are directed their sharp tops towards the sharp prongs of basic elements, and are in the same plane, that primarily affects the elements and, furthermore, the central portion of the tape is reinforced with an elastic element in the form of wire, preferably of circular section fixed and held on the belt rolled edges of the central portion of the tape, according to the proposal of the basic and additional striking elements are arranged at different angles towards to each other along the tape, varies from 0 ° to 90 °, and provided with one or more spines arranged perpendicular to the longitudinal axis of the tape.

In addition, the reinforcing wire can be to improve the reliability, except for rolling, additionally soldered to the central portion of the tape, as well as the entire tape with the reinforcing wire can be covered with a corrosion-resistant coating for longer duration.

Furthermore, each tine damaging elements can be deployed in opposite directions or in one direction relative to the longitudinal axis of the tape.

Besides the spikes on the main and additional striking elements may be turning away from the plane of these damaging elements.

Location of the main and additional elements different angles along the axis of the tape allows receiving the latter with bulky affecting properties, i.e., in this case, either side cannot capture or hands to press the tape. Supply tape perpendicular to the studs located on the main and additional striking elements, excludes the possibility of manipulating the tape without painful hand injury to the latter, which also increases the barrier-protective properties of the proposed barbed tape.

Reliability of fastening the reinforcing wire to the central portion of the tape, as well as coverage of its anti-corrosion coating provides a barbed tape workable for a long time without changing its physical properties.

Thus, barbed tape with the proposed design changes acquires new properties that let you create high-performance for a long time without changing the physical properties of the barrier an obstacle to prevent unauthorized access to a protected object.

Further essence of the proposed technical solution is explained in conjunction with illustrative material, showing the following:

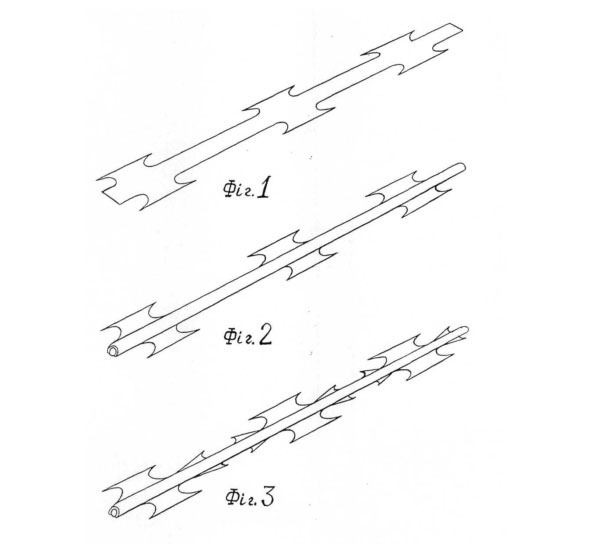

- Figure 1 – general view of a flat barbed tape without reinforcement (the analogue of Ukraine patent №41834);

- Figure 2 – general view of the barbed tape to the central portion, reinforced wire (the analogue of Ukraine patent №33526 U);

- Figure 3 – general view of the barbed tape to the central portion, the reinforced wire, and with the additional striking elements (prototype of the USA Patent №4844422);

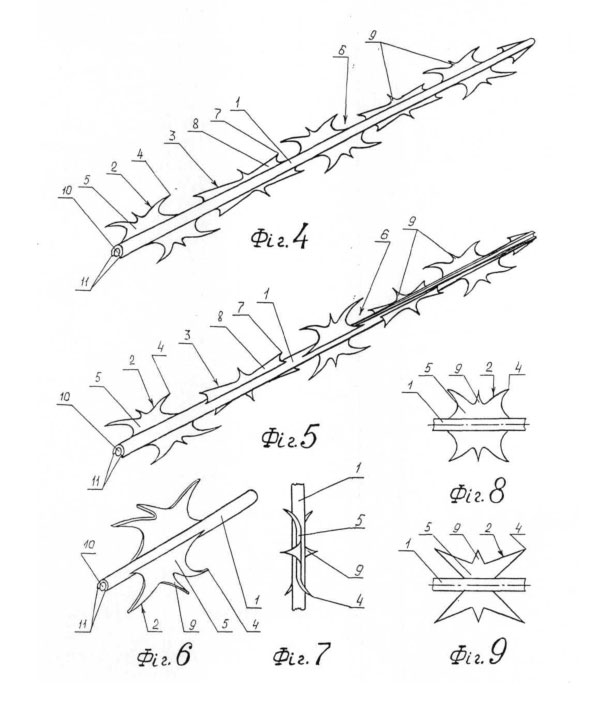

- Figure 4 – general view of proposed barbed tape to the central portion, the reinforced wire, with basic and additional striking elements and spines arranged in one plane (the angle of the installation of main and additional striking elements relative to each other is 0°);

- Figure 5 – perspective view of the barbed tape offered to the central portion, the reinforced wire, with basic and additional striking elements and spines arranged at an angle relative installation to each other 45°;

- Figure 6 – a general view of the proposed piece of barbed tape with curved spikes relative to the plane of the main striking element;

- Figure 7 – a side view of the proposed fragment barbed tape with prongs deployed in opposite directions relative to the longitudinal axis of the tape;

- Figure 8 – a top view of a proposed barbed tape fragment to the main element affecting a circuit formed by curved edges;

- Figure 9 – a top view of the proposed barbed tape fragment to the main element affecting a circuit formed by straight edges.

Proposed rolled reinforced barbed tape is made of a metal (e.g., cold rolled galvanized steel) strip and consists of a central portion 1 and a large number of opposing pairs of basic elements 2 and other damaging elements 3 formed integrally with the central portion of one metal strip. Pairs of basic and additional damaging elements 2 and 3 are located along the section 1 uniformly (although this is not mandatory, but adherence to uniformity i.e. in the manufacture of more sophisticated). The distance between the pairs of basic elements 2 arranged side by side, it is in the range, for example, 30-60 mm. Each element in a pair of main elements 2 consists of opposing prongs 4 and 5. Acute basis of each prongs 4 are splay 5 with bases prong 4. Between each pair of two main elements affecting both sides of the central portion 1 is formed inside the wide space 6, which is limited externally to sharp prongs 4 basic elements 2. Within the wide area 6 are additional elements 3, 7 prongs cusps are directed towards sharp prongs 4 basic elements 2. Basis of 8 additional elements 3 height slightly less than 5 basic fundamentals elements 2 so tine 4 and 7 are arranged on different levels, which, together with their counter-oriented, increases retention effect. The main and additional striking elements 2 and 3 are provided with one or more studs 9 disposed perpendicularly to the longitudinal axis of the tape. These spikes 9 may be located in the same plane with the bases 5 and 8 of the basic and additional elements 2 and 3, respectively, and perpendicular thereto, wherein both curved in the same direction or in different directions. Furthermore, each main and additional striking element 2 and 3, the prongs 4 and 7, respectively, may be deployed in opposite directions or in one direction relative to the longitudinal axis of the tape. Equipment perpendicular spiked 9 eliminates the possibility of capture tape without painful hand injury last, which increases the protective properties of barbed tape. In order to save metal strips from which barbed tape is made, pins 9 basic elements 2 of its height does not extend beyond the overall width of the main striking element 2 and the studs 9 other damaging elements 3 may extend beyond the overall width of the additional striking element 3 but do not extend beyond the overall width of the main striking element 2.

Primary and secondary elements 2 and 3 may be arranged at different angles to each other along the tape. This angle can vary from 0 ° to 90 °. Location of the main and additional elements 2 and 3 at different angles around the strip makes the latter with bulky affecting properties, i.e. in this case from either side or impossible to capture arms to press the tape. The central portion of the tape 1 is reinforced elastic central wire 10, preferably of circular section, which is fixed and held thereon rolled edges 11 of the central portion 1 of the tape. Reinforcing wire 10 is to improve the reliability of fastening of the tape along its entire length, except for rolling may further be soldered to a central portion of one tape. All news together with the wire 10 may be coated with anti-corrosion coating. Increased reliability of fastening the reinforcing wire 10 to the central portion of the tape 1 by soldering, as well as cover its anti-corrosion coating to make a bid barbed tape workable for a long time without changing its physical properties.

Further essence of the proposed technical solution is explained in conjunction with the principle of rolled reinforced barbed tape operation.

When you try to overcome the barrier fence erected using the proposed barbed tape, prongs 4 and 7, along with studs 9, hold the offender without inflicting serious wounds and injuries, and counter-thrust of prongs 4 and 7 increases retention effect (works like a harpoon) tape fragments of clothing and body intruder. If you try to get rid of rolled traumatic tip of the prong 4 main striking element 2 clothing offender will inevitably fall on the tip of the prong 7 additional striking element 3 and on the tip of the prong 4 main striking element 2 located nearby. This increases the retention effect by several adjacent pairs of basic and additional damaging elements 2 and 3. The spikes 9 exclude the possibility to free yourself from the prongs 4 and 7 by manipulating the tape in the space of his hands. Location of the main and additional damaging elements 2 and 3 at angles relative to each other making a tape " inaccessible" to either side and does not leave any chance to the attacker or offender be released on the tape of the proposed design. Have rigid reinforcing wire 10 does not allow to cut the barbed tape without the use of special devices, and press it against the ground, allowing you to build a reliable barrier security of protected sites, and stick to a certain humanity, without causing serious wounds and injuries offender prongs 4 and 7, as well as spikes 9 tape.

Naturally, the contour of the additional striking elements 2 and 3 may be formed as curved edges (8) and the straight edge (9). The essence of this proposal is not changed. It is also natural that the spikes can be asymmetrical, more technologically for the organization of almost non-waste production, as well as on each striking elements 2 and 3 can be placed not one, but several spikes 9.

Significant distinction of the proposed technical solutions of previously known such solutions is that the main and additional elements tape provided with spikes, and in that mentioned studs and the basic and additional striking elements and their prongs deployed about the longitudinal axis of the belt at different angles. These differences, together, allow obtaining the barbed tape affecting bulk properties that significantly increase its holding ability and inability to manipulate by hands. No barbed wire can possess the above mentioned properties, since it does not have in their structures perpendicular to the tape axis studs and have a flat design, which reduces their consumer and protective properties.

The proposed technical solution is tested in practice that allows us to consider its suitable for industrial applications. In the well-known sources of information it is not found such a barbed tape marked in the offer essential features and indicated technical result, and therefore is considered to be such that it can receive legal protection.

The technical advantages of the proposed technical solution, in comparison with the prototype include the following:

- Increase the barrier properties due to the gradual turn to an angle of basic and additional damaging elements along the barbed reinforced tape;

- Increase the barrier properties of the amazing properties bulk of reinforced barbed tape;

- The inability to manipulate reinforced barbed tape with hands due to the presence of spikes perpendicular to the main and additional elements;

- Increase the barrier properties due to the impossibility of cutting the tape without using special tools because of the central reinforcing wire;

- Long-term preservation of elastic properties and shape for the same reason;

- Reinforcing wire solidity to the central portion of the tape due to the additional brazing;

- Using well-known techniques (rolling and brazing) for fastening reinforcing wire at a central portion of the tape;

- The reliability of the reinforcing wire retention at a central portion due to its continuous fixing the entire length of the tape;

- Good aesthetic appearance of the product due to the fact that the material of the central portion of the covering (hide) reinforcing wire;

- Resistance to local loads and temporary changes in shape due to the high elastic properties of the tape;

- Does not require the application of non-standard materials for the reinforcing reinforcement, it is made of ordinary wire.

Social benefits from the use of the proposed technical solution, in comparison with prototype, obtained by increasing the reliability of protected objects and due to the impact of humanity on the attacker or intruder at the arrest barbed tape and the inability to get rid of it on their own tapes.

Economical effect of the proposed technical solutions usage, in comparison with the prototype was prepared by increasing consumer properties without increasing the cost of tape and increases the consumption of materials.

After the description above mentioned rolled reinforced barbed tape specialists will appreciate that all of the above is merely illustrative, and not limiting, having been presented by this example. Numerous modifications and other embodiments of the elements of the barbed tape, in particular methods fastening reinforcement wire, its size and shape of the cross-sectional size and shape of spikes, the prongs of basic and additional striking elements may vary in different ratios and constructively and clear are within the scope of one of ordinary and natural approaches in the given area and are considered as staying within the scope of the technical solutions.

The quintessence of the proposed technical solution is as follows: the main and additional striking elements are provided with perpendicular spikes may be positioned at different angles relative to each other and relative to the longitudinal axis of the tape, and it is possible to gain these circumstances proposed barbed tape above and other advantages. Fabrication, modification and use of only certain elements of other tape, of course, limit the range of the benefits listed above, and cannot be considered as a new technical solution in this field, as more similar to that described, the implementation of the barbed tape does not require any creativity from designers and engineers, and therefore cannot be considered as the result of their creative activity or a new object of intellectual property protection enforcement relevant documents.

Claims

- Rolled reinforced barbed tape formed of metal strip and comprising a central portion with a large number of pairs of oppositely directed major destructive elements formed integrally with it and located in the same plane, and a pair of main elements located along the central area of the tape with a uniform pitch, and also every main striking element in a pair consists of a base and opposing prongs, formed on a side of the element, and the tips of each of the prongs are angles formed between the outer and inner sides of the striking element, wherein between the sides of the major destructive elements located adjacent is formed inside the wide space of external constraints sharp prongs themselves basic elements, and within mentioned wide area there are additional elements, prongs which are directed their sharp towards the sharp prongs of basic elements, and are in the same plane as the main elements and, moreover, the central portion of the tape is reinforced with an elastic element in the form of wire, preferably of circular section fixed and held on the belt rolled edges of the central portion of the same tape, characterized in that the basic and additional striking elements are arranged at different angles relative to each other along the tape varies from 0 to 90 °, and provided with one or more spines arranged perpendicular to the longitudinal axis of the tape.

- Rolled reinforced barbed tape according to claim 1, is characterized in further reinforcing wire is soldered to the central portion of the tape, and the whole tape with the reinforcing wire is covered with corrosion-resistant coating to increase the duration.

- Rolled reinforced barbed tape according to claim 1, is characterized in that each tine elements deployed in opposite directions or in one direction relative to the longitudinal axis of the tape.

- Rolled reinforced barbed tape according to claim 1, is characterized in the spikes on the main and additional striking elements to turn away from the plane of these damaging elements.