- Security barrier which comprises at least one protective element with one or several barbed tape or coils of barbed wire Egoza and its supporting units installed at certain intervals from each other, characterized in that the protective member is a shaft on the outer cylindrical surface of which is fixed, preferably radially, a plurality of razor-barbed damaging elements in the form of tapered pins, with coils of barbed wire wound rectilinearly or helically on the mentioned shaft or a straight or spiral sharpened pins and supporting units are arranged in the form of racks bearings at the upper end, which accommodate the shaft ends of the protective element to allow circulation of the latter.

- Security barrier as claimed in claim. 1 is characterized by the shaft of the shielding member is positively driven to rotate.

- Security barrier as claimed in claim. 1 is characterized by the shaft which is fixed, and its outer cylindrical surface formed by tube clad on the shaft.

- The security barrier according to claims. 1-3, which is characterized in the barbed cutting submunitions have additional striking elements in the form attached to them in a chaotic manner symmetrical or sharpened needles or spikes of different lengths, or they are wrapped around barbed wire.

The utility model belongs to the field of building security installations and systems, which include razor-barbed elements and can be used for the manufacture of security barriers, which are used to prevent unauthorized entry of people and animals on sensitive sites.

Famous fencing to protect against thieves, which comprises a horizontal bar of a metal bracket fixed to the vertical column and vertical shaft, which are welded to mentioned crossbar with a certain interval. Poles and made of rolled metal shaft with straight dihedral angles. At the ends of the poles and shaft there is length each direct dihedral angle to form a taper at one end [see Russian Federation patent № 2296203 in class E04H 17/14 published in 27.03.2007].

The main disadvantage of this is the lack of fences protecting its properties. This disadvantage is explained as follows. Since the fence has a flat structure and shaft is installed at regular intervals, you can easily take hold of the horizontal bar between the shaft and easy to climb over the fence without damaging of the wedge, and thus penetrate the regime object.

This disadvantage is eliminated in the security barrier "Dikobraz", which consists of a set of spherical protective elements, each of which includes a reinforced twisted barbed tape wound on the wire-base or barbed tape compression at the portion of the side surface of the wire-base, which suites in space frame . The space frame is formed in the shape of a sphere formed meridional windings wound or crimped barbed tape and rigid equatorial ring installed inside the coils wound or crimped barbed tape. Coils wound or crimped barbed tape bonded to each other at the poles of the sphere and the equatorial ring. The first spherical protective element is attached to a vertical or inclined stand at the poles of the sphere and on-site security border. Further, adjacent to the first spherical protective element and further disposing the second protective spherical elements similar to the entire length of the security boundary [see Russian Federation patent №2272113 from the class E04N 17/04 published in 20.03.2006].

The main drawback of the safety barrier is that spherical protective elements are not bonded to each other along the length of the security boundary. Therefore, any one of them is easy enough to disrupt or delay, for example, taking an ordinary hook behind barbed tape to form a free passage through the protective line as the rest of the spherical protective elements do not preclude such failure or limb of one of them. It is this fact reduces the effectiveness of the protection of sensitive sites using a known security barrier.

The closest in its essence and the attainable effect, and which is accepted as the prototype, it is a security barrier, which includes at least one protective member formed in a twisted spiral barbed tape with multiple supports nodes established with a certain interval from each other. Security element in the form of spirals of barbed wire can be multiple, and the spiral may have different diameters, base section and a vertical section, between which is placed a spiral barbed tape. The turns of the spiral sections are attached to the support site that allows you to create horizontal and vertical resistant barrier [see The international application WO 2007/078307 of the number of class V21F 25/00 published in 12.07.2006].

The main disadvantage of the given protective fence is its low barrier properties. It’s quite easy to overcome, due to the real estate of the security element. This disadvantage is explained as follows. Fixed security element easily covers any sheet material, for example, a tarpaulin, and that is how to completely eliminate the razor-barbed action of the elements affecting the security barrier. Moreover, submunitions, on the contrary, in this case, to provide assistance to an attacker, holding the canvas material spike barbed tape from slipping, which could allow an attacker to further smoothly climb over the security barrier and thus penetrate the regime object.

Another significant disadvantage of the known protective boom is its low technical properties. The presence of this shortcoming is due to the following. The security element fence made of barbed tape that is easy to eat, even the conventional metal shears, that's violating the integrity of the security element and thus forming a free passage to the regime object.

At the base of the utility model the task of raising the technical and operational characteristics and protective properties of the security barriers due to the impossibility of destroying its integrity over the entire length or placing it any coatings to neutralize the harmful effect of razor-barbed submunitions by the security element movable relative to their supporting units.

This object is achieved in that the security barrier, which includes at least one security element of one or several barbed tapes and its supporting components, which are mounted with a certain interval from each other, according to the proposal, the protective member is a shaft on the external surface of the cylinder is fixed, preferably radially, a lot of cutting-piercing submunitions in the form of pointed pins, with barbed tape wound in a straight line or in a spiral on the mentioned shaft in a straight line or in a spiral on the pointy pins. The support units are arranged in a rack with bearings at the upper end, which is placed in the shaft ends of the protective element to allow circulation of the latter.

To enhance the effect of repelling or aggressiveness of the security element, the shaft may have a protective element positively driven by its rotation.

As the variant for fulfilment, the shaft may be fixed, and its outer cylindrical surface formed by tube clad on the shaft. The essence of the proposed technical solution does not change: his piercing-cutting submunitions are turning all one. Thus the tube can be made not continuously over the length, and a set of rings, which makes independent rotation of the individual razor-barbed submunitions over the entire length of the security element. To enhance the aggressive and destructive properties of razor-barbed submunitions, pins may have additional elements in the form set out for them in a chaotic or a symmetrical manner pointed needles of different lengths, or spines or be wrapped with barbed wire.

Due to the fact that the protective element is moving (turning in the horizontal plane), it is impossible to fix any cover or grab hold of the pins and fit. In both cases, the load applied to the eccentric pin about the axis of the shaft-treatment under the action of which the shaft bearing twist and will not allow an attacker to climb over the protective element.

Thanks to razor-barbed submunitions in the form of quite thick pins, they cannot be removed (snap) conventional technical means, such as a pair of scissors for metal.

Due to the barbed tape on the shaft and tapered dowels, space between them is completely blocked.

Thus, the proposed security barrier achieves a technical result of the task at hand, namely the improvement of technical and operational and consumer characteristics, in particular – security.

Further essence of the utility model is explained in conjunction with illustrative material, showing the following:

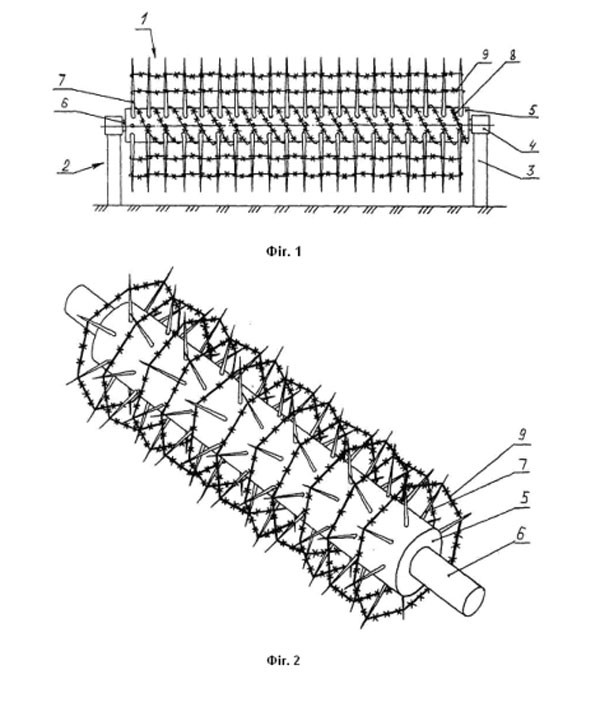

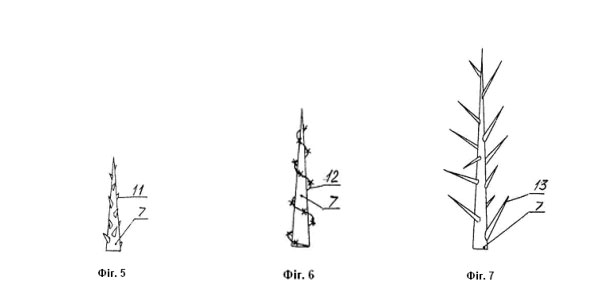

- Figure 1 – section of protective boom assembly, front view, a variant with solid shaft with pins under bearings and barbed tape helically arranged on the shaft in a straight line on the tapered pins;

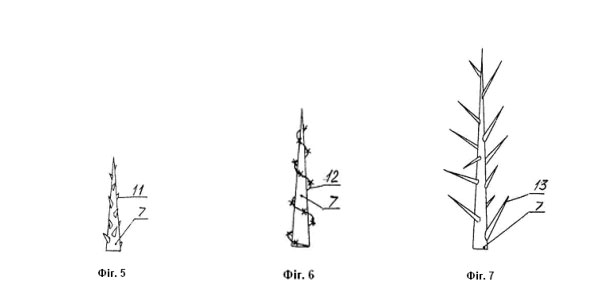

- Figure 2 – a plan view of the security element, a variant with a solid shaft length by bearings, and barbed tape helically arranged on pins;

- Figure 3 – the same embodiment with the fixed shaft, on which a continuous tube is clad with pins and barbed taped which is located on a straight pipe;

- Figure 4 – the same embodiment with the fixed shaft, on which wearing pipe barbed tape and helically arranged rectilinearly on the tube and on the straight and spirally tapered pins.

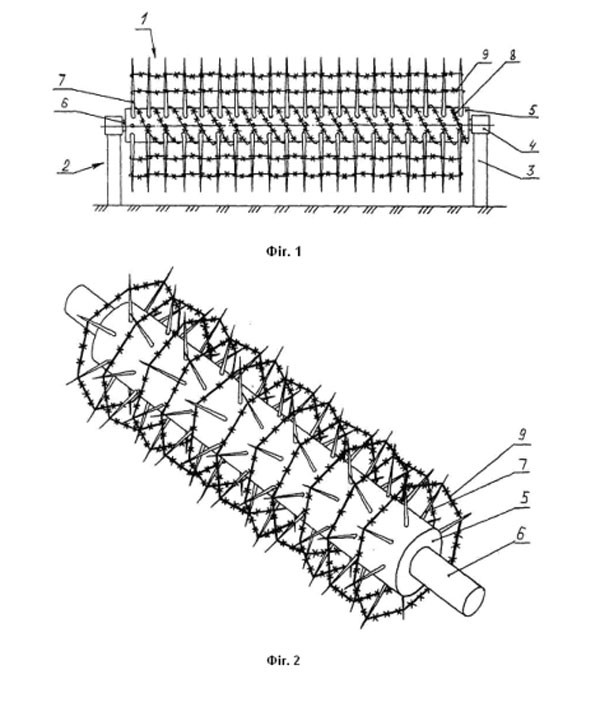

Variants of the razor-barbed submunitions:

- Figure 5 – pin with sharp spikes;

- Figure 6 – pin coiled barbed tape;

- Figure 7 – pin with sharp needles.

Each section of the proposed security barrier comprises a protective element 1 is situated predominantly horizontally and mounted on its supporting nodes 2. Supported units 2 are designed as mainly vertical uprights 3 with the radial bearing 4 at its upper end.

Razor-barbed tape is 8 (wound) in a straight line or in a spiral on the shaft 5. A similar barbed tape is 9 (wound) in a straight line or in a spiral on the sharpened pins 7.

The security element 1 is designed as a shaft 5 length 6 with fastening shaft 5 in radial bearings 4, 5 so that the shaft is free to turn around its longitudinal axis.

On the outer cylindrical surface of the shaft 5 is fixed, e.g., welded or mounted on the thread, preferably radially, a plurality of barbed cutting damaging elements in the form of sharpened pins 7.

To enhance the repellent effect, the shaft 5 of the protective element may be provided with rotational drive force of any known design (they are not shown because of its well-known). Forced rotation of the shaft 5 with pins 7 greatly increases the aggressiveness of the security fence and is used when an attempt to penetrate the regime object becomes apparent.

As fulfilled variant, the shaft 5 can be made fixed, and its outer surface is formed by a cylindrical tube 10 freely clad shafts 5. The essence proposal does not change: the pins 7 and its barbed tape 8, and 9 are still rotating about the longitudinal 5 the shaft axis.

To enhance the damaging properties of the pins 7, they may be in the form of additional elements mounted on them in a chaotic manner, or symmetric spikes 11, or wrapped with barbed tape 12, or pointed needles of different lengths 13. The proposed security barrier works as follows: when you try to grab attacker 7 pins for the hands and catch the shaft 5 rotates, and pins 5, which seized arms, will be below and above them will be other neighboring radial pins 7, which does not climb over the protective element 1. In an effort to interceptions for other pins 7, all happen again thanks to the next rotation of the shaft 5 in the bearings 4. The same is going to happen when you try to cover the protective element 1 in any sheet material: climbing on the material, because of the eccentricity, shaft 5 will rotate, giving an attacker to climb a security element 1. Jumped at shaft 5 between the pins 7 do not allow barbed tape 8 and 9. Therefore, climb over the proposed security barrier is not possible.

In addition, the presence on pins 7 more damaging elements in the form of pins 11, 12 or barbed tape pointed needle 13 generally excludes the possibility of their girth hands, even to a greater extent the proposed increases the barrier properties of the security barrier.

As cutting-piercing submunitions in the form of a fairly thick pin 7, cannot be deleted (snap) conventional technical means, for example, metal shears, which further improves the reliability of the protection of sensitive sites.

The significant difference of the claimed technical solutions from the first known is the fact that the security element is movable, in particular rotatable, and razor-barbed submunitions are designed as rather thick pin and can be fitted with striking elements in the form of spikes, sharpened needles or barbed tape. And also the fact that the shaft and the tapered pins mounted rectilinearly or helically barbed tape. These differences, together, eliminate any possibility of overcoming the protective element due to its rotation in the case of giving it to a load and lack of access to the space between the pin. These circumstances suggest the proposed security barrier almost insurmountable. None of the prior art security barriers can possess mentioned properties, because they are stationary or protective elements, or made of thin material and elements, whose integrity is easily destroyed using ordinary locksmith tools.

The proposed technical solution tested in practice. The security barrier "Egoza-Alligator" does not contain any elements or nodes that cannot be replicated at the present stage of development of science and technology, particularly in the manufacture of safety barriers and security barriers is therefore acceptable for industrial applications, has the technical and other benefits before known such technical solutions for the proposed principle of mounting a protective element to support his units and equipment of submunitions, which confirms the possibility of achieving a technical result of the claimed subject, in certain sources of information is not revealed these security barriers from those in the offer essential features, but because it relies so that can get legal protection.

The main technical advantages of the proposed technical solutions, in comparison with the prototype are the following:

- Increase the protective properties due to the fact that the protective element is turning relative to the support of its elements;

- Improving the technical and operational characteristics due to the impossibility of destroying the integrity of its razor-barbed submunitions conventional means;

- Increase the barrier properties by equipping the shaft and tapered pins barbed tape;

- Increasing destructive properties by equipping razor-barbed submunitions additional striking elements;

- It increases the effect of repelling force by rotation of the security element;

- Improving the efficiency and reliability of the protection of sensitive sites.

Social benefits from the implementation of the proposed technical solution are compared with the prototype obtained by the impossibility of penetrating sensitive sites due to the high reliability of protection.

The economic effect is obtained by reducing crime, particularly theft of storage and other facilities due to their guaranteed reliability from thieves, terrorists and other criminals.

After the description of the proposed security barrier, specialists in the given area should be apparent that all of the above is merely illustrative, and not restrictive, and is presented this example. Numerous possible modifications protective or damaging elements, in particular their amount, size, used actuators and bearings, variants of barbed tapes, may vary in different ratios and, of course, within the scope of one of ordinary and natural approaches in the following area and treated such that they are within the scope of this technical solution.

The quintessence of the proposed technical solution is that the protective element is turning, and razor-barbed elements are equipped with additional striking elements as plug and razor-barbed, and that these factors, combined, allow the proposed security barrier have listed other advantages. Change and use of only the individual components of the security barrier, naturally limits the range of benefits, and cannot rely on new technical solutions in the given area, as similar to that described security barrier will no longer require any creativity of designers and engineers, and therefore cannot relying result of their creative activity and new intellectual property that fall under the protection of protection document.