Patent of Ukraine: №91445

Author: Tkachenko Yuriy Vladimirovich

Section of the IPC: B21F 25/00 – Barbed wire, mesh, fencing, wire fabrics

Published: 26.07.2010, Bulletin № 14/2010

Rolled reinforced barbed tape – Ukrainian Patent №91445

- Rolled reinforced barbed tape is formed from a metal strip having a central portion and a large number of opposing pairs of basic elements which are integrally formed thereon, and a pair of basic elements are arranged along the central area of the tape uniformly, and each basic element consists of paired bases and oppositely directed spikes made of external sides of the element, and the tips of each spike are angles formed between the outside and the sides of the element, wherein between the sides adjacent to the pairs of basic elements formed wide internal space bounded outside spikes these basic elements, and in the wide spaces are additional striking elements spikes are directed cusps towards to spikes basic elements, and the central portion of the tape is reinforced with spring wire preferably of circular section, which is fixed and held thereon by rolled edges of the central area of the tape, is characterized by the primary and secondary elements are positioned at different angles around the tape (0 to 90 degrees to each other) and equipped with one or more spikes arranged perpendicular to the longitudinal axis of the tape.

- Rolled reinforced barbed tape of 1 point is characterized by the reinforcing wire to improve the reliability and immobility fastening additionally soldered to the central portion of the tape and the entire tape is coated with anticorrosion coating wire.

- Rolled reinforced barbed tape according to 1 or 2 points, which is characterized in each main and additional elements spikes deployed in opposite directions or in one direction relative to the longitudinal axis of the tape.

- Rolled reinforced barbed tape as claimed in claim 1-3, characterizes in the spikes on the main and additional elements deployed in opposite sides or one side of the plane of said elements.

- Rolled reinforced barbed tape in one of 1-4, characterizes in the pairs of spikes and the main and additional elements are arranged asymmetrically relative to the central area of the tape.

The invention relates to hardware production, namely, the production of barbed tape that is used for the construction of safety barriers designed to prevent unauthorized penetration of sensitive sites.

The well-known barbed wire, which is made of a metal strip with punched along the axis of symmetry perforations grooves in stellate spikes which are fixed, are inserted into the grooves of the tape at an angle oriented in the opposite direction from the other. From other angles tape is bent around the spike and crimped, and between the grooves is twisted around its longitudinal axis [see copyright certificate USSR № 519 256 from the class B21F 25/00 published in 25.06.1976].

The main drawback of the barbed wire includes the complexity of its fabrication, and because of this the high cost and unreliability of the stud affixing positions in the tape.

It is also well-known serrated tape, which is derived from a metal strip and comprises a central portion and a large number of opposed pairs of elements, formed integrally with it. Each element is provided with a pair of first and second external spikes and third and fourth with the inner, which are formed by punched tape in oval recesses [see the USA patent №4887796 in class B21F 25/00 published in 19.12.1989].

The main disadvantage of the given serrated tape is its lack of humanity that is a form of external spikes facilitates application of serious wounds and injuries. There is relatively large distance between the axe of symmetry of the adjacent pairs of cells that do not provide sufficient effect of retaining fragments of clothing and body intruder. The high cost of tape manufacturing due to the fact that it is made from stainless steel, the processing of which requires a relatively large energy consumption, increased depreciation of equipment and stamping property as metal stamping with its stamping irrational, namely due to a specific form of the external and internal spikes form large metal waste.

There is also well-known barbed tape which comprises a central portion and a large number of opposed pairs of elements, integrally formed with it, wherein a pair of elements disposed along the central section of the tape evenly, and each element in the pair comprises a base and opposing spikes that are made of external sides of the element. Each of the spikes acute angle is formed between the outer side and the sides of the element, wherein between the sides of elements disposed near the pair of elements is constituted by a wide inner space bounded outside spikes of these cells [see Patent of Ukraine № 41834 of class B21F 25/00 published in 24.04.2001].

The main disadvantage of the barbed tape is that it is impossible to use it to secure the construction of the barrier fence due to insufficient technical and functional properties of the barbed tape. Firstly, the barbed tape is made of sheet metal, and it is easy to bite without the use of special tools for this, even normal household scissors, and in this way affect the integrity of the protected object enclosure. Secondly, because the famous barbed tape does not have sufficient spring properties, and because of the small thickness of the metal from which it is made, the fence made of this tape is fairly easy to deform, such as pressed to the ground, even with a stick, and easily enter the protected area. Moreover, the tape, after deformation, is not restored to its original position.

These disadvantages are eliminated in the barbed tape, which comprises a central portion and stamped on its outer edge with a decreasing keystone spikes to the bottom corner. Wherein the tape further comprises a reinforcing wire of circular cross section, to form its core spun or crimped tape or adjacent to the surface of the central portion and spikes of different sides are opposed to each other [see Russian patent № 68386 U1 classes B21F 25/00, 29/00, F41H 11/08 published in 27.11.2007].

The main disadvantage of this barbed tape is the ability of core separation from the tape during flexing, since the contract between the tape and the core takes place only on the tangent line. This drawback is eliminated in the rolled reinforced barbed tape which is formed from metal strip and comprises a central portion and a large number of opposed pairs of elements, formed integrally with it. Wherein a pair of elements disposed along the central area of the tape uniformly, and each element in the pair comprises a base and opposing studs made of external sides of the element. Each of the spike acute angles is formed between the outer side and the sides of the element; wherein between the sides of elements disposed near the pair of elements is constituted by a wide inner space bounded outside spikes of these elements. Moreover, the central portion of the tape is reinforced with a spring wire, preferably of circular section, which is fixed and held thereon seamed edges of the central portion of the tape. Reinforcement tape core wires, for example, steel of high with pronounced spring properties itself pasture central portion during the operation of rolling the wire from a flat shape to a cylindrical, adds tape enough rigidity and elasticity to retain and restore the original form, given its manufacturer during production. Barbed tape with such properties constitute a highly efficient, long lasting retaining the original form a physical barrier designed to prevent unauthorized access to a protected object. [see the Patent of Ukraine № 33526 U in Class B21F 25/00 published in 25.06.2008].

The main disadvantage of this barbed tape is insufficiently effective retarding properties, in particular if the attacker's clothing catches on the spike, it is easy to release, because this action does not interfere, because in the construction of the tape opposite and directional elements do not exist, together with retaining spines formed harpoon effect.

The most similar in nature and effect, which is achieved, and that is taken as a prototype, is rolled reinforced barbed tape which is formed from a metal strip, and comprising a central portion with a large number of opposing pairs of basic elements integrally formed with it, and is in the same plane. Moreover, the basic elements of a pair are arranged along the central area of the tape uniformly, and each core element in the pair comprises a base and opposing spikes made of external sides of the element, and the tips of each of the spike is the corners which are formed between the outer and the cell sides. Thus between cell sides positioned near the pairs of basic elements is formed inside the wide space which from the outside is limited spikes of these basic elements and in wide spaces are additional spikes, with sharp directivity toward spikes basic elements, which are also coplanar with basic elements. Moreover, the central portion of the tape is reinforced with a spring wire, preferably of circular section, which is fixed and held thereon rolled edges of the central portion of the tape.

Reinforcement tape core wires, for example, steel of high with pronounced spring properties itself to the very central portion during the operation of rolling the wires from the flat shape to the cylindrical adds tape enough rigidity and elasticity to retain and restore the initial shape, given its manufacturer during manufacturing [see the USA patent № 4844422 in class B21F 25/00 published in 30.07.1987].

Despite the fact that the additional pronged elements increase the retention effect, the location of the main and additional elements in the same plane, and decreases its overall barrier properties, since flat tape is easy to press or push even with a palm of the hand, drawing it on a plane to which are not directed serrated elements. In addition, the basic elements can freely embrace hand, since the tip of the spikes are arranged parallel to the central axis, or tape, or at some slight angle away from it, that is, they cannot cause hand injury. The same bias tape you can make with the help of additional elements, if the space between the main elements will be wide enough so that you can stick your hand, not clinging to the prongs of the main affecting elements.

Hence the well-known design rolled reinforced barbed tape is unreliable, and therefore it is considered unimproved, because you can freely to influence it (move, turn down), even without injury to the hands, and even more injuries. At the base of the invention, the aim set is to increase barrier-protecting consumers' physical properties rolled reinforced barbed tape by increasing the damaging effect by arranging the gear elements in different planes along the length of the barbed tape and equipping its striking elements extending from its central longitudinal axis to almost perpendicular.

This task is achieved by the fact that the well-known rolled reinforced barbed tape formed of metal strip, comprising a central portion and a large number of opposing pairs of basic elements which are integrally formed with it, wherein a pair of basic elements are arranged along the central area of the tape evenly. Also, each main element of the pair with the base member and oppositely directed spikes made of external sides of the element, and the tips of each spike are the corners which are formed between the outer side and the cell sides. At the same time the parties are located near the main elements of steam which is formed inside the wide space, which is limited to the outside spikes these essential elements, and in the wide spaces are additional spikes directed towards basic elements. Moreover, the central portion of the reinforced tape is with spring wire, preferably of circular section, which is fixed and held thereon rolled edges of the central portion of the tape. According to the proposal, the main and additional elements are arranged at different angles around the strip (0 to 90 degrees) to each other, and are endowed with one or more spikes arranged perpendicular to the longitudinal axis of the tape.

Furthermore, to improve reliability, the reinforcing wire may be further rolled additionally soldered to the central portion of the tape, and the whole tape with the conductor may be further coated with corrosion resistant coating.

Besides each damaging elements can have the prong which can be deployed in opposite directions or in one direction relative to the longitudinal axis of the tape.

Furthermore, the spikes on the main and additional elements can be deployed from the plane of mentioned elements.

Location of the main and additional elements at different angles around the strip makes affecting bulk properties of the latter, i.e. in this case, either side cannot be captured or with hands to press the tape. Equipment tape perpendicular spikes, located on the main and additional striking elements, eliminates the possibility of bias tape without painful hand injury to the latter, which also increases barrier protective properties of barbed tape.

Reliability of fastening the reinforcing wire to the central portion of the tape, as well as coverage of its anti-corrosion coating enables a bid barbed tape workable for a long time without changing its physical properties.

Thus, barbed tape with the proposed design changes, acquires new properties that allow you to form a highly efficient, long time without changing the physical properties inherent obstacle barrier to prevent unauthorized penetration of the protected area.

Further essence of the proposed technical solution is explained in conjunction with illustrative material, showing the following:

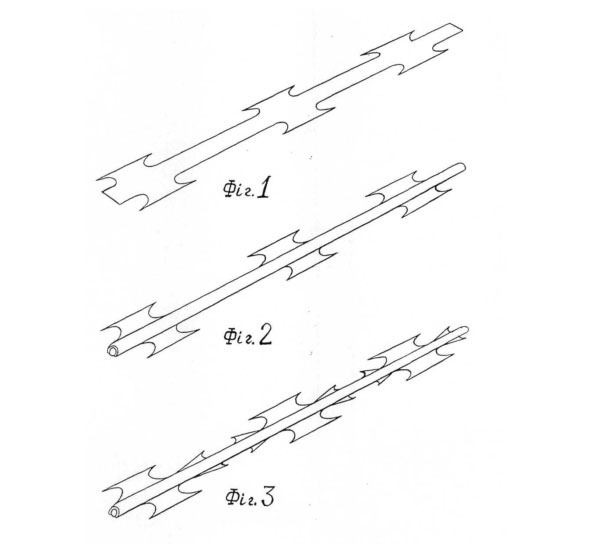

- Figure 1 – general view of a flat barbed tape without reinforced wire (analogue to the patent of Ukraine № 41834);

- Figure 2 – general view of the barbed tape to the central portion, with reinforced cable (analogue to the patent of Ukraine № 33526 U);

- Figure 3 – general view of the barbed tape to the central portion, wire reinforced, and additional striking elements (prototype of the USA Patent № 4844422);

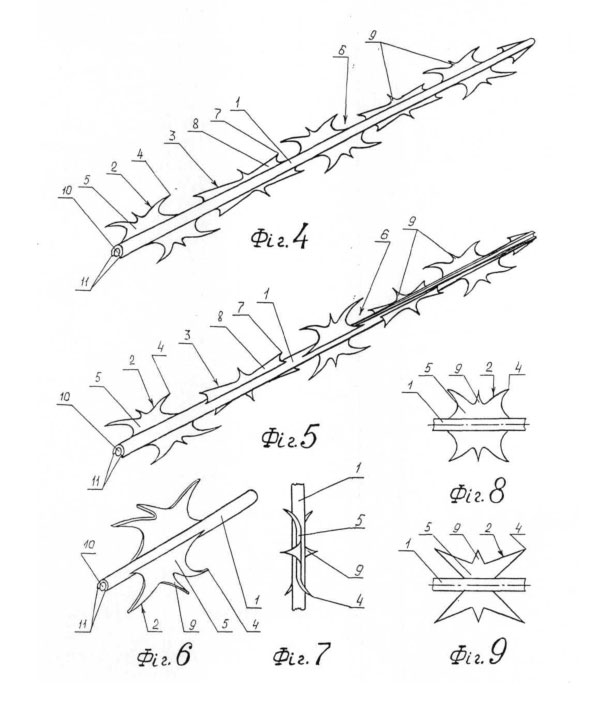

- Figure 4 – general view of proposed barbed tape to the central portion, the reinforced wire, with basic and additional striking elements and spikes arranged in one plane (the angle of rotation relative to each other is equal to 0°);

- Figure 5 – general view of proposed barbed tape to the central portion, the reinforced wire, with basic and additional striking elements and spikes arranged at an angle of rotation relative to each other which is equal to 45°;

- Figure 6 – a general view of the proposed fraction of barbed tape with curved spikes due to the plane of the striking element;

- Figure 7 – a side view of the proposed fragment barbed tape with prongs that are deployed in opposite directions relative to the longitudinal axis of the tape;

- Figure 8 – a top view of a fragment of the proposed barbed tape to the main element affecting a circuit formed by curved edges;

- Figure 9 – top view of a fragment of the proposed barbed tape to the main element affecting a circuit formed by straight edges.

The proposed sharp and cutting reinforced tape is made of a metal (e.g., cold rolled galvanized steel) strip and consists of a central portion 1 and a large number of opposing pairs of basic elements 2 and additional elements 3, integrally formed with portion 1. The pairs of elements 2 and 3 are arranged 1 evenly along sections (although this is not mandatory, but more technologically uniform compliance). The distance between the pairs of core elements 2 arranged side by side, it is in the range, for example 30 – 60 mm. Each element in a pair of core elements 2 comprises opposing studs 4 and 5. The base of each spike 4 is the angles that are the conjugate base 5 with a spike 4. Between each pair of core elements 2 on both sides of the central portion 1 is formed inside the wide space 6 which is bounded externally cusps spikes 4 main elements 2. Inside the wide area located 6 additional items 3, 7 spikes which tops meet spikes 4 main elements 2. The base 8 additional elements 3 is somewhat smaller than the bottom 5 basic elements 2, so the studs 4 and 7 are located on different levels, which, together with their opposite directions, increases the retention effect. Core 2 and additional elements 3 are endowed with one or more spikes 9 disposed perpendicularly to the longitudinal axis of the tape. These spikes 9 may be located in the same flatness with the bases 5 and 8, and two additional basic elements 3, respectively, and perpendicular thereto, and can be folded in one direction, or different.

Furthermore, each main and additional two tine elements 3 4 and 7, respectively, can be turned in opposite directions or in one direction relative to the longitudinal axis of the tape. Equipment tape perpendicular spiked 9 eliminates the possibility of bias tape without painful hand injury last, which increases the protective properties of barbed tape. For the economy, metal strips which make up the tape, pins 9 core elements 2 in their height does not go beyond the overall width of the base member 2 and the pins 9 additional members 3 may extend beyond the overall width of the additional element 3, but not beyond the beyond the overall width of the base member 2. Core 2 and additional elements 3 may be arranged at different angles to each other along the belt. This angle can vary from 0 to 90 degrees. Location of the main 2 and additional elements 3 at different angles around the strip makes affecting bulk properties of the latter, i.e. in this case, either side cannot capture or press the tape with hands.

The central portion of the tape 1 is reinforced with a central spring wire 10, preferably circular cross-section, which is fixed and rests on rolled edges 11 of the central portion 1 of the tape. Reinforcing wire 10 to enhance the reliability of the entire length of the tape except rolling may additionally be soldered to the central portion of one tape. The entire trio together with the wire 10 may be coated with anti-corrosion coating. Increased reliability of fastening the reinforcing wire 10 to the central portion of the tape 1 is soldered and covered with anti-corrosion coating, to make a bid barbed tape workable for a long time without changing its physical properties.

Further essence of the proposed technical solution is explained in conjunction with the principle of operation of rolled reinforced barbed tape. When you try to overcome the barrier fence, which is manufactured using the proposed barbed tape, pins 4 and 7, along with spikes 9, hold the offender without inflicting serious wounds and injuries, and the opposite direction of spikes 4 and 7, increases retention effect (it works like a harpoon) tape fragments of clothing and body intruder. If you try to get rid of catchy traumatic tips of the spikes 4 offender clothing clings to the edge of the spikes 7 additional element 3 and 4 of the basic element 2, which is located nearby. This increases the effect of holding several, located close to the major pairs 2 and 3 additional elements. Spikes 9 preclude be released from the spikes 4 and 7 by manipulating the tape in the space with the help of hands. Location of the main 2 and 3 additional elements at angles makes tape " inaccessible" to either side and does not leave any chance to the attacker or offender be released on the tape of the proposed design. The presence of solid wire 10 does not allow cutting the barbed tape without the use of special devices, and pressing it to the ground, allowing you to securely form a safety barrier of protected sites, and keep certain humanity – without causing serious injury and injury offender spikes 4 and 7, as well as spikes 9 tapes.

Naturally, the contour of the additional striking element can be formed as a curvilinear edge (FIG. 8) and the straight edges (FIG. 9). The essence of the proposal remains the same. It is also natural that the spikes can be asymmetrical, more technologically for almost waste-free production, as well as on each element may not be one but several spikes.

Significant distinction of the proposed technical solutions of the previously known similar solutions is, that the main and additional submunitions belt endowed with spikes, and in that the said pins and the most basic and optional elements and their barbs are deployed about a longitudinal axis of the belt at different angles. These differences, together, make a bid tape barbed tape with volume striking elements that significantly increase its holding property and the inability to manipulate it. No barbed wire possesses distinguished properties because it does not have spikes in their design but has a flat design that reduces their protective properties.

The proposed technical solution is tested in practice, which gives reason to believe it suitable for industrial applications. In the sources of information it is not revealed a similar barbed tape indicated in the offer essential features, but because it is assumed such that the need to obtain legal protection.

The technical advantages of the proposed technical solution, as compared to the prototype include the following:

- Increase the barrier properties due to the gradual turn to an angle of basic and additional damaging elements along the axis of reinforced barbed tape;

- Increase the barrier properties of the bulk of the damaging properties of reinforced barbed tape;

- The inability to drag barbed reinforced tape hands due to the presence of spines on the basic and additional elements;

- Increase the barrier properties due to the inability to cut the tape without the use of special means of the presence of the central conductor;

- Saving spring properties and shape for a long time for the same reason;

- Reinforcing wire is mounted to the central portion of the tape due to his extra rations;

- The use of known technologies (rolling and brazing) to strengthen the reinforcing wires in the central portion of the tape;

- A reinforcing wire is mounted on the central portion due to its consolidation throughout the length of the tape;

- Good aesthetic appearance due to the fact that the material of the central portion wraps (hide) reinforcing its lead;

- no susceptibility to temporary local stresses and changes shape due to the high spring properties of the tape;

- Do not require the application of non-standard materials for the reinforcing wire; it is made from a standard wire.

Social benefits from the use of the proposed technical solution, as compared with prototype, obtained by increasing the reliability of protected sites, and due to the impact of humanity on the attacker or intruder at his arrest barbed tape and at the same time, it is impossible to get rid of their own tapes.

Economical effect of the use of the proposed technical solutions, in comparison with the prototype was prepared by increasing consumer properties without increasing the cost of the tape and increasing costs of materials.

Having described above mentioned rolled reinforced barbed tape specialists in this area will appreciate that all of the above is merely illustrative, and not limiting, having been presented by this example. Numerous modifications and other embodiments of the elements of the barbed tape, in particular, methods of strengthening reinforcement wires, its size and shape of the section, the size and shape of spikes, prongs basic and additional striking elements may vary in different ratios and constructively that course, is in within the scope of one of ordinary and natural approaches knowledge in the art and are considered to be within the scope of the technical solutions.

The quintessence of the proposed technical solution is basic and additional submunitions endowed spikes can be arranged at different angles relative to each other and relative to the longitudinal axis of the strip, and this fact allows you to purchase the proposed tape above and other advantages. Fabrication, modification and use of only certain elements of the tape, of course, limit the range of these benefits, and cannot rely on new technical solutions in the area, because otherwise, like the one described, the execution of barbed tape does not require any creativity of designers and engineers, and therefore cannot rely on the results of their creative activity and new intellectual property to be protected by security documents.