Patent of Ukraine: №102841

Author: Tkachenko Yuriy Vladimirovich

Section of the IPC: B21F 25/00 – Barbed wire, mesh fencing, wire fabrics

Section of the IPC: E04H 17/04 – Hedges, fences, corrals, characterized by the use of wires of special purpose, such as barbed wire

Published: 08.27.2013, Bulletin № 16

Reinforced barbed tape made of composite materials – patent of Ukraine №102841

The invention relates to a wire production, namely, to the production of barbed tape, are used as a safety barrier. The tape includes a central portion and a large number of pairs of opposing elements integrally formed with it. A pair of elements arranged uniformly along the belt. Each element in the pair comprises a base and opposing prongs, formed from the outer side member, and the tips of each of the prongs are angles formed between the outer side and the sides of the element. Between the sides of elements, adjacent pairs of elements is formed an interior space which is bounded externally sharp prongs of these elements.

The tape is made of composite material which prevents corrosion of the reinforcing wires, e.g., of plastic or glass cloth impregnated with epoxy resin. In the inside of the central thickened portion further poured in the molding belt, for example, extrusion, metal wire of any cross-section of ordinary steel. Technical advantages of the invention: the absolute resistance to corrosion and environmental influences, increasing resource use, reducing the total weight, the expansion of technical and functional characteristics of the central section, providing aesthetic appearance; Waste-free production; simplification of the manufacturing process, reduce the cost of the product, reliable connection to the base wire reinforcing tape.

The invention relates to hardware production, namely, the production of piercing-cutting ribbons used as safety barriers designed to prevent unauthorized penetration of sensitive sites, and can be used in the manufacture of protective armored barbed tape of any design and purpose.

The given barbed wire consisting of a steel strip, in which are punched along its axis of symmetry, the perforation slots in which are mounted stellate spikes inserted in the slots of the tape at an angle which is oriented in the opposite direction from the other and from other angles the tape encircle around stud rolled and, between the grooves, twist around its longitudinal axis [see the copyright certificate USSR № 519 256 from the class B21F 25/00 published in 25.06.1976].

The main disadvantage of the known barbed wire should include the complexity of the manufacture of the product, and because of this – its high cost and unreliability of fastening spikes in the tape – you can easily straighten and remove the tape, violating the protective properties of the safety barrier.

The given barbed wire, which consists of a base made of weathering steel spikes having an integral structure with a base, which are arranged symmetrically on both sides of the base and rotated around the axis of bases with respect to each other at the same angle of not more than 90 °, wherein each pin can be formed, pyramid-shaped or arrow [see Russian Federation patent №2197355 in class B21F 25/00, published in 27.01.2003].

The disadvantage of this barbed wire is the complexity of its manufacturing process, which is caused by the need to perform complex spatial spikes with design and orientation relative to each other and to the base.

Also barbed tape, comprising a central portion and a large number of opposed pairs of elements, integrally formed with it, wherein a pair of elements disposed along the central area of the belt uniformly, and each element in a pair consists of a base and opposing prongs, formed on the outer sides element, and the tips of the prongs are each of the angles formed between the outer side member and sides, with elements between the sides, adjacent pairs of elements is constituted by a wide inner space which is bounded externally sharp prongs of these cells [see the Patent of Ukraine № 41834 of class B21F 25/00, published in 24.04.2001].

The disadvantage of the given barbed tape is its low technical and functional properties.

First, the well-known tape is very easy to damage (for example, you can have a meal in any toolbox, even ordinary household scissors), because it is made of sheet metal. Secondly, the tape is not known to have sufficient spring properties and has a small thickness, because of which it is easy and reversibly deformed by mechanical effects. So, from a known barbed tape is impossible to create a reliable barrier protection.

The most similar in nature and reaching effects, taken as a prototype, is reinforced with barbed tape comprising a central portion and a large number of opposing pairs of elements, integrally connected thereto, and a pair of elements arranged along the central portion of the tape evenly, and each element pair consists of a base and opposing prongs, formed from the outer side member, and the tips of each of the prongs are angles formed between the outer side and sides element, wherein between the sides of elements, adjacent pairs of elements formed by the internal wide area which is externally bounded cusps prongs of these elements, and the central portion of the tape is reinforced central elastic wire of high carbon steel, preferably of circular section fixed and held on the tape of its inner rim of the central portion.

The main drawback of the known piercing and cutting reinforced tape is that it is made entirely of metal, in particular from a metal tape and the metal wire. It is known that the metal exposed to corrosion, so the production of a barbed tape to completely maintain its technical and functional properties for a long period of operation should be used or galvanized metal or stainless steel that is very expensive materials. Otherwise, when using low quality, so-called "black" metal, barbed tape famous a year later becomes unsuitable for further use. Reinforcement of such tapes should also be carried out exclusively high quality; high carbon galvanized steel wire rope or spring.

Another essential disadvantage of the known piercing and cutting reinforced tape is that its connection with the main part of the reinforcing wire occurs by rolling the latter into the central portion of the tape. This type of connection is not sufficiently reliable: if the local bend the tape, for example, in the construction of the barrier – quite common, necessary and ordinary operations – the edge of the central portion inevitably straighten releasing reinforcing wire, which is why the tape is automatically loses its protective properties, namely those for which it reinforced. In addition to rolling, this is an additional step complicates production, with the result that, again, increases the cost of production.

There is also a significant disadvantage of the known barbed tape is the presence of large metal waste due to inefficient metal cutting at stamping spike elements of this tape.

Thus, considering the above facts, armored barbed tape, made on the basis of the prior art, has a high cost (use of expensive metal), has a short term serviceability (fast natural corrosion of metal) is waste (inappropriate technology), and therefore in the end, is quite expensive, which is why, especially given the need for a large number of linear meters for the construction of safety barriers, it becomes unattractive to most potential customers.

The basis of the invention is to extend the life of the operation and reduce the cost of manufacturing a reinforced barbed tape by improving its technical and functional characteristics by changing the material for the tape and the reinforcing wire connection type with a central portion of the tape.

This object is achieved in that the reinforced piercing and cutting the tape, comprising a central portion and a large number of opposed pairs of elements, integrally formed with it, wherein a pair of elements disposed along the central area of the belt uniformly, and each element in a pair consists of a base and an oppositely directed prongs formed with the outer side member, and the tips of each of the prongs are angles formed between the outer side and sides element, wherein between the sides of elements, adjacent pairs of elements is formed inside the wide space outwardly bounded sharp prongs of these elements, and a central portion reinforced tape according supply tape is completely made of plastic or any composite material such as fiberglass impregnated with epoxy resin, wherein the central portion of the tape is made thicker and functions as a reinforcing wire. To give further elastic properties to the inside of the central thickened portion can further be infused when forming tapes, for example, extrusion, metal wire of any cross-section of ordinary steel.

Proposed reinforced barbed tape, plastic has improved technical characteristics: it does not corrode under the influence of precipitation is manufactural in production (non-waste technology – removing particles back into the process), rather elastic, it has an unlimited service life and less weight on the compared to similar products made from steel.

The thickened central portion of the tape requires no additional reinforcement, since he performs its function. Thus, the proposed reinforced barbed tape is made of only one type of material, greatly simplifies its production.

At the same time, modern plastics are virtually unlimited performance, so for the production of the proposed reinforced barbed tape it is possible to select an optimal set of plastic with these characteristics, the relevant purpose and the specific conditions of use (in most cases using a high-strength refractory hard plastic). In order as material may be any composite material such as glass cloth impregnated with epoxy resin.

In addition, the proposed reinforced piercing-cutting of plastic tape has more aesthetic appearance due to the possibility for the customer to change the color of plastic, aggressive or masking.

This additional reinforcement of the central portion of the metal wire, the wire rolling operation disappears – it was poured with plastic tape into a unitary structure during its manufacture. Link integrity bases tape with reinforcing metal wire eliminates the risk of corrosion on the surface of the latter, so you can use a wire of steel of ordinary quality (i.e. N. "Black steel"), which is much cheaper galvanized or stainless steel. This helps to significantly reduce the cost of the finished product. Moreover, this type of compound (pour) no requirement for a reinforcing wire configuration – it can be any section (round or rectangular), and the thickness is limited only by the thickness of the central portion of the plastic tape.

Thus, the totality of the essential features of the proposed technical solution regarding the reinforced piercing-cutting strips of composite materials ensures the achievement of the technical result.

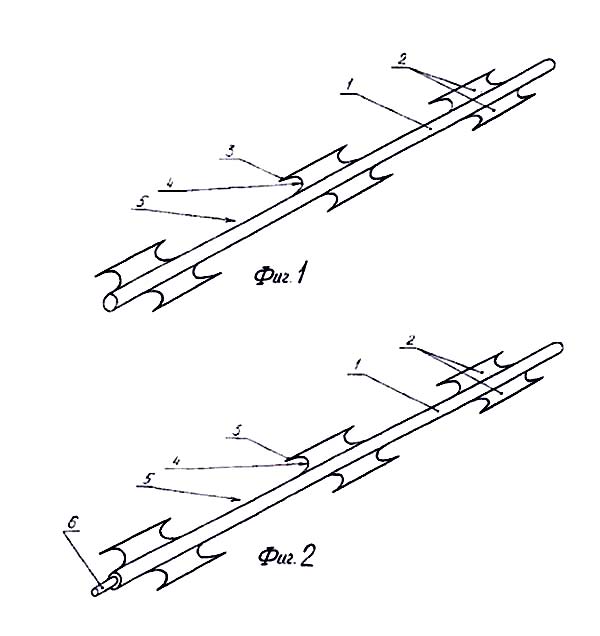

Further essence of the proposed invention is explained in conjunction with illustrative pictures in which:

- Figure 1 – a general view in plan reinforced piercing and cutting a tape of composite material;

- Figure 2 – the same, with the additional reinforcing metal wire in the central portion.

Asking reinforced piercing and cutting feed is made, respectively, of a plastic (e.g., high fire-retardant plastic) tape consisting of a central portion 1 and a large number of opposed pairs of elements 2 integrally formed with portion 1. The pairs of elements 2 are disposed along one portion uniformly. The distance between the pairs of elements 2 arranged side by side, it is approximately 30 mm. Each element of the two paired elements comprises prongs 3 and 4. The bases of the prongs of each island are three angles which are conjugate bases of the prongs 4 3. Between each pair of elements 2 on both sides of the central portion 1 forms an inner space 5 is wide, limited external sharp prongs 3. The central portion 1 is made thicker, for example, round, and can be reinforced with a glove in his metal wire 6.

Proposed reinforced barbed tape of composite materials is as follows. When you try to overcome the barriers made of this reinforced barbed tape prongs 3 elements 2 hold the offender without inflicting serious wounds and injuries, and the inner wide space 5 between pairs of elements 2 enhances the retention effect of the tape with respect to fragments of clothing and body offender caught in the space of 5 and is held by a directed towards each other prongs 3 adjacent pairs of elements 2, limiting the size of the space 5. If you try to get rid of traumatic tip of a prong 3, the offender gets on the tip of the prong 3 element 2 adjacent pairs of elements 2, directed toward the first prong 3, as the distance between the axis of symmetry of the adjacent pairs of elements 2 is chosen optimally for the purpose, and is, for example, 30 mm. This increases the retention effect by several adjacent pairs of elements 2.

The presence of thickened reinforcing the central section 1 without a wire 6 or it does not allow to cut the piercing and cutting the tape without using special devices, and press it to the ground, allowing you to create robust security barrier for protected sites and stick with the principles of humanity – not to cause serious wounds and injuries offender prongs 3 tape.

Significant distinction of the proposed technical solutions similar to the previously known solutions is that the piercing and cutting of the tape is made of a composite material, and its central portion is thickened or reinforced by further supplementing the metal wire.

These differences, in the aggregate, can increase the life operation without time constraints and improve the technical and functional properties of a barbed tape at the same time simplify the manufacturing technology and can reduce its cost. No known barbed tape cannot simultaneously possess these properties, because they are generally not made from composite materials and do not have the permanent connection with the reinforcing wire, which fully protects it from corrosion.

The proposed technical solution was tested in practice. Proposed reinforced barbed tape composite does not contain any elements or nodes that cannot be replicated at the present stage of development of science and technology, particularly in the production of piercing-cutting ribbons, therefore, it is suitable for industrial applications, has the technical and other advantages over known analogs, confirming the possibility of achieving technical result of the claimed subject. In the known sources of patent and other scientific and technical information not found such reinforced piercing-cutting strips of composite materials specified in the offer set of essential features, so the proposed solution it is considered to be such that it can receive legal protection.

The technical advantages of the proposed technical solution, compared with the prior art, include the following:

- Absolute resistance to corrosion and environmental influences due to use for the base of a plastic or composite material;

- Increase operational life (life service of virtually unlimited) for the same reason;

- Reduction of the total weight of the product for the same reason;

- Extension of technical and functional characteristics of the central portion due to the performance of its thickened;

- Ensuring the aesthetic appearance of the product, and hence the expansion of its scope of application with the ability to easily change the color of the plastic;

- Non-waste production due to return directly to the process cut pieces of plastic.

If the central portion further reinforced, the technical advantages:

- Simplification of the manufacturing technology by eliminating the additional step of rolling the wire reinforcement;

- Reducing the cost of the product by allowing the use of relatively cheap for the reinforcement of the wire, for example, of black steel;

- Providing the ability to use tape for reinforcement wire of any cross section and the thickness by connecting the mastic tape-based wire into a unitary structure by injection;

- Increasing the reliability of the connection to the base of the reinforcing wire barbed tape for the same reason;

- The absence of specific requirements for production material mounting metal for the construction of reinforced barbed tape safety barriers due to the inertia of plastic.

Social benefits from the implementation of the invention, compared with prior art, obtained by compliance with the principles of humanity in relation to offenders and improve aesthetics of safety barriers sensitive sites.

The economic effect from the implementation of the invention, compared with prototype, obtained by reducing the cost of products, increasing the attractiveness, because of which – an increase in sales volumes.

After describing the aforementioned reinforced barbed tape of composite materials by those skilled in the art it should be understood that all of the above is merely illustrative, and not limiting, having been presented by this example. Many possible embodiments of the proposed reinforced barbed tape of composite materials, in particular, characteristics and marks composite or plastic, steel grade reinforcing wire, its dimensions and shape of the section may vary and, of course, within the scope of one of ordinary and natural approaches knowledge in the art and are considered those that are within the scope of this technical solution.

The quintessence of the proposed technical solution is that the base tape is made of plastic or other composite material, and its central portion is reinforced or thickened or pour into a metal wire, and it is this fact allows you to purchase the proposed tape above and other advantages. Fabrication, modification and use of only certain elements of the belt, of course, limits the range of the benefits listed above, and cannot be considered as new technical solutions in the field of knowledge, because otherwise similar to that described, performance reinforced piercing-cutting strips of composite materials is not required or creativity of designers and engineers, and therefore cannot be considered the results of their creative activity and new intellectual property, suitable for the protection of title documents.

Claims

- Reinforced barbed tape, comprising a central portion and a large number of opposed pairs of elements which are integrally formed with it, wherein a pair of elements disposed along the central area of the belt uniformly, and each element in a pair consists of a base and opposing prongs, formed from outer side member, and the tips of each of the prongs are angles formed between the outer side and sides element, wherein between the sides of elements, adjacent pairs of elements is formed an interior space which is outside the limited cusps of the prongs of these elements, and the central portion of the tape is made reinforced, characterized in that the central portion of the tape is made thicker, is externally circular shape in cross section and is reinforced in a glove with a flexible steel wire of any section, wherein the tape is made of a composite material, which prevents corrosion of the reinforcing wire.

- Reinforced barbed tape according to Claim. 1, characterized in that the tape is made of plastic or glass cloth impregnated with epoxy resin.